Production

and business management software

for the packaging industry

Automate

Accelerate

Analyze

HiFlow offers ERP Class MIS software for the packaging industry that optimizes and accelerates your packaging business. It’s an end-to-end modular solution that provides you with the data and analysis you need to scale and grow.

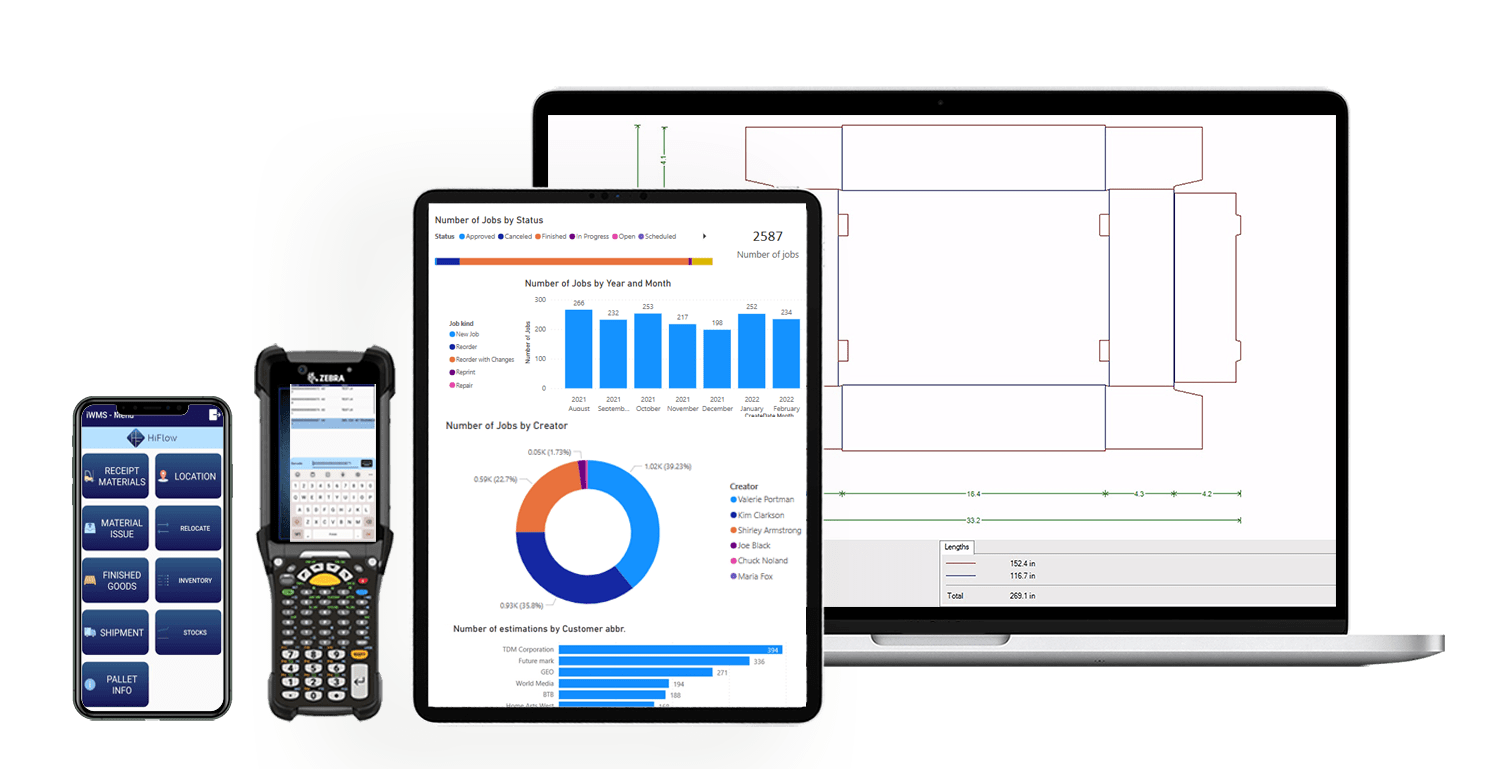

JOB & CUSTOMER

MANAGEMENT

Customer Service, Estimating, Centralized Database, Quote Generation, Sales Planning

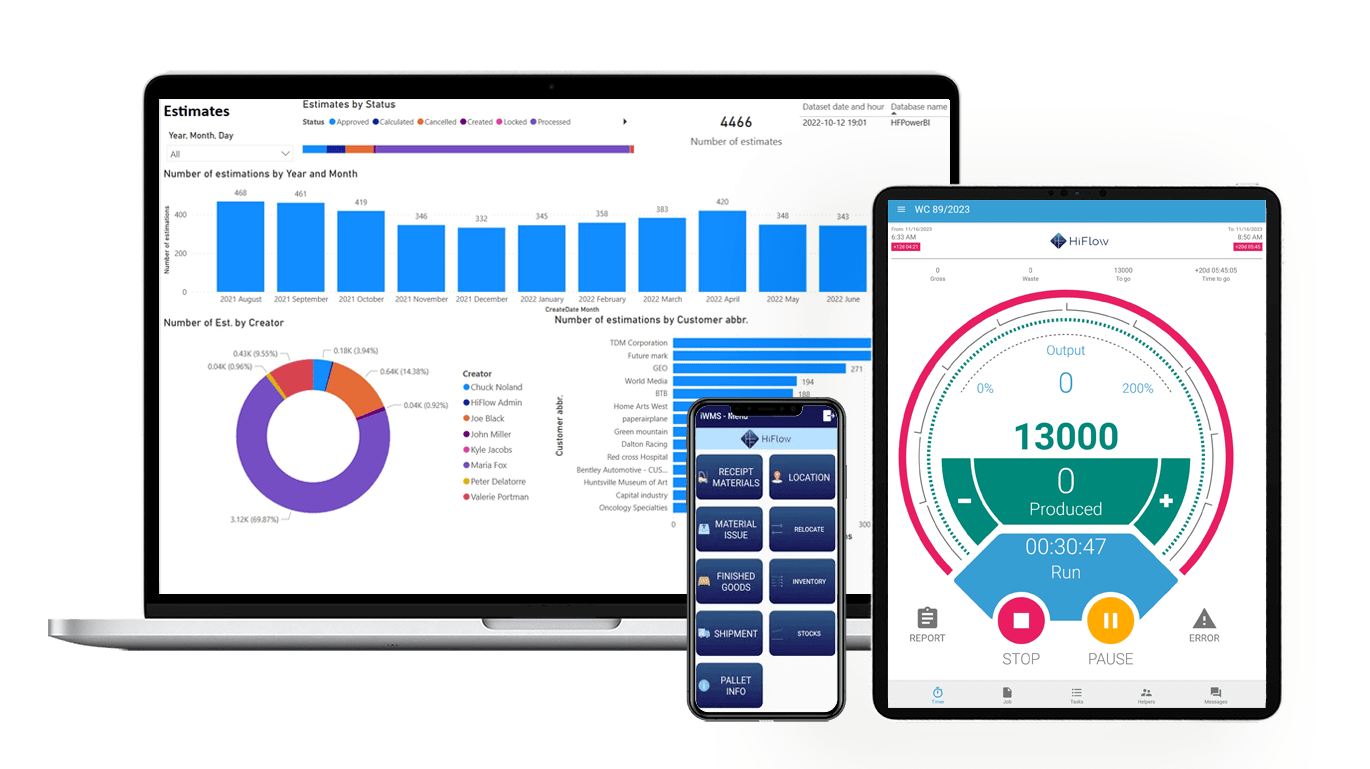

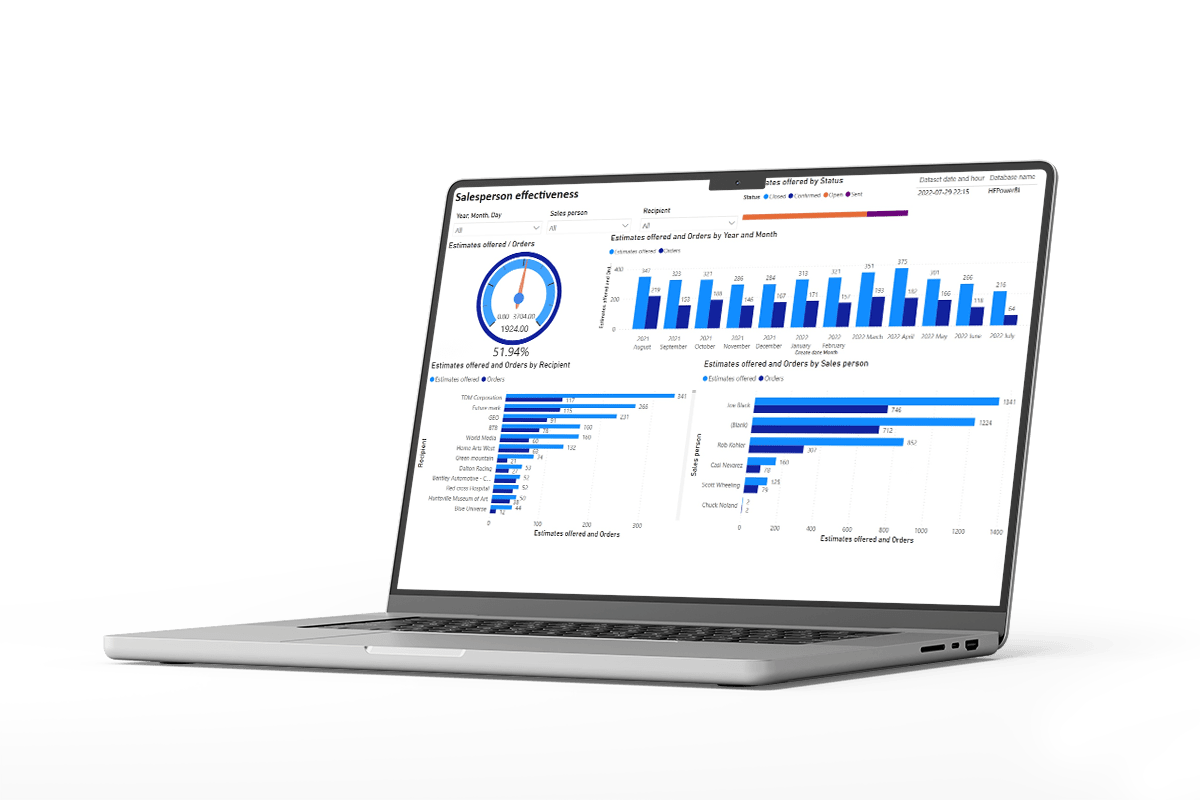

BUSINESS

INTELLIGENCE

Dashboards, Deep Data Collection, Reporting, Material Forecasting

PRODUCTION

VISIBILITY

Scheduling, Visual Workflow, Shop Floor, Tools Management

WAREHOUSE

OPTIMIZATION

Product inventory, Barcode Management, Batch Traceability

HiFlow by the

numbers

years of development

satisfied clients

worldwide users

You are not just a customer. We partner with you during implementation and beyond to help you achieve your business and production goals.

Read about how companies like yours have increased efficiency, reduced labor costs, and leveled up in the marketplace.

Our automation solution can deliver:

Easy integration with Open APIs

Shorter order processing times

Fewer input errors, fewer touches

Operational transparency in Scheduling

Shop floor interaction with scheduling

Continuous automated data collection

Less waste and rework

Full integration of shop floor data collection

Visual Workflow

Our automation solution can deliver:

Easy integration with Open APIs

Shorter order processing times

Operational transparency in Scheduling

Fewer input errors, fewer touches

Shop floor interaction with scheduling

Continuous automated data collection

Less waste and rework

Visual Workflow

Full integration of shop floor data collection

Industries

Served

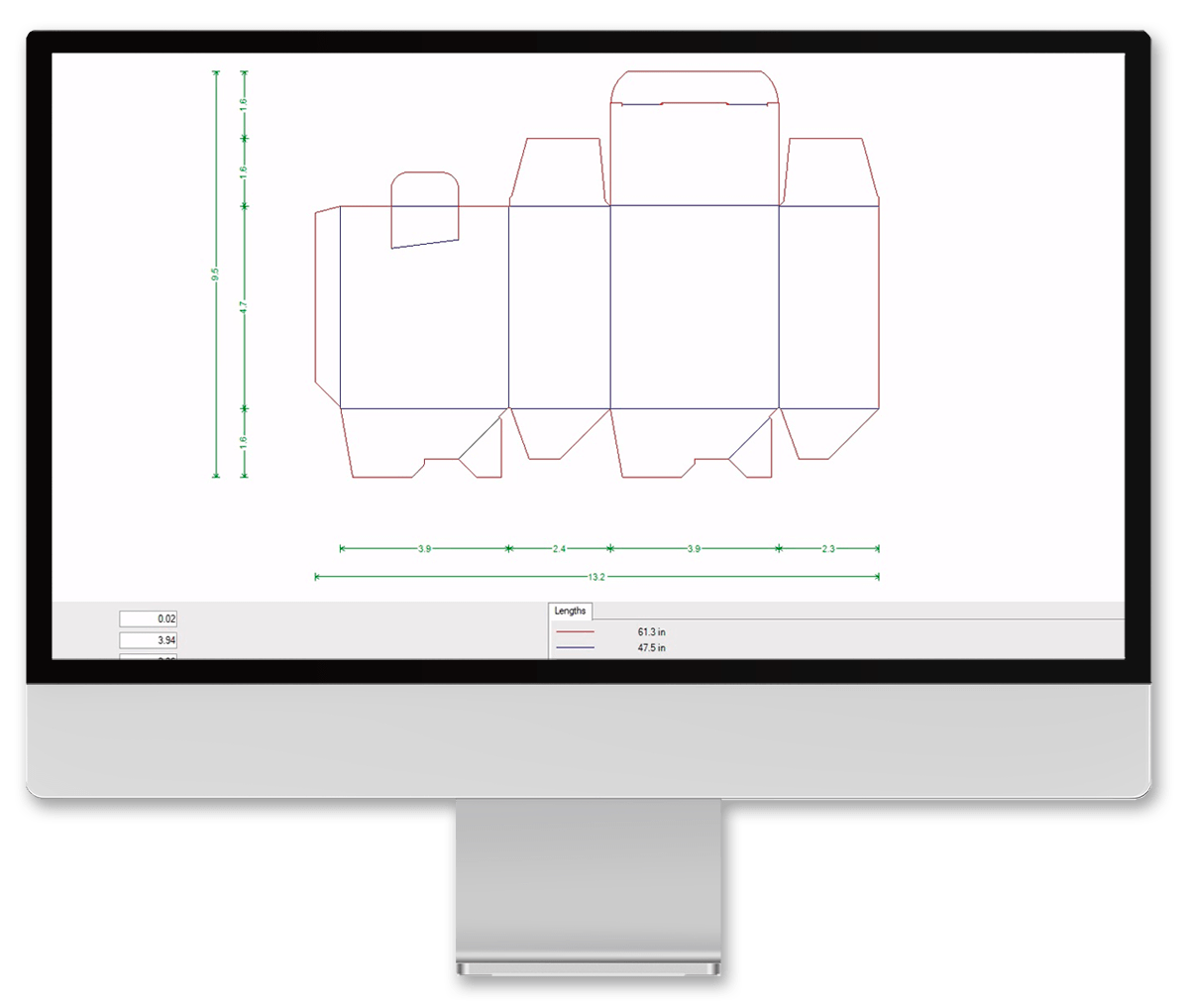

Folding

Carton

more

Labels

& Tags

more

Flexible

Packaging

more

Corrugated

Converters

more

Commercial

Printing

more

Solutions

SALES & CUSTOMER

SERVICES

Get quotes out FAST.

Follow customers & jobs in

real time. Give CSRs the

tools they need to improve

CX & increase sales.

PRODUCTION

PLANNING

Automate and visualize your plant’s entire production planning and scheduling processes.

FINANCIAL

Save clicks & time with

automation and a

connected workflow.

Empower collaboration

between all departments.

SHOP FLOOR DATA COLLECTION

Make data-driven decisions

by streamlining production

workflows, automating data

collection. Insights in real time.

INTEGRATION & COMMUNICATION

Strengthen operational efficiency, foster collaboration, and elevate competitiveness through enhanced integration and communication strategies.

PRODUCTION PREPARATION

Quash any bottlenecks before they occur and move jobs into production quickly, while maintaining quality control.

WAREHOUSE

Reduce operating expenses

through automation. Increase visibility and traceability with

real time inventory.

Analytics

Collect and analyze the

millions of data points your

plant produces into the

actionable insights you need.

Trusted by these leading brands

The management system that automates and accelerates your

packaging business

From the onboarding of a job through final invoicing and shipping, HiFlow MIS is the umbrella solution that covers your entire business and production ecosystem. With over 70 configurable modules, we tailor our software to fit your unique packaging business. Start with a few key modules and expand over time as new requirements emerge. Our expert consultants work with you to determine the most appropriate path forward for your business.

Streamline

& Simplify

HiFlow provides an MIS solution powered by Industry 4.0 that supercharges efficiency by streamlining processes with easy-to-use visual tools.

Connect

& Integrate

HiFlow connects data, applications, software, and devices across your entire organization, making it more efficient, productive, and agile. It ensures that everything-and everyone works together with one accurae set of data.

It’s all

about the Data

HiFlow offers you powerful tools to collect data across your entire business and production ecosystem. The result? Real- time data and predictive analytics to future-proof your business and support fact-based decision making.

Use HiFlow’s customizable Dashboards to see the data driven insights most relevant to each role in your organization.

Automation

The heart of HiFlow

Automation reduces the time required to process an average production order through your plant. It begins at job creation by automating an estimator’s tasks…

HiFlow automates systems across your business from scheduing, production and inventory to customer service and sales.

Design Your Perfect

Solution! Craft Your

Ideal Setup – Cloud or On-Premises.

Design Your Perfect Solution! Craft Your Ideal Setup – Cloud or On-Premises.

Have More Questions?

The Comprehensive

Q&A to HiFlow 4.0

- What is an MIS for packaging?

- What’s the difference between HiFlow and ‘out of the box’ ERP systems?

- I am a medium-sized commercial shop expanding into folding carton. Can you help me?

- Can I configure the solution to meet my future needs?

- I already have prepress software (i.e., Esko) that the team loves. Can you integrate with it?

- How long is the implementation period? Is your staff available to help us throughout this period?

MIS for the packaging industry Ready for a tour of HiFlow 4.0?

Schedule a walk-through of the HiFlow solution designed around your specific pain points and the unique needs of your plant…

Find out how our demos are structured and what to expect.