ERP for Flexible Packaging

Manufacturers

Cost Control,

Visibility & Compliance

HiFlow offers an end-to-end MIS solution for Flexible Packaging companies.

Warehouse Optimization

HiFlow’s unique system consists of modules that manage your warehouse processes efficiently and effectively, even when you have multiple locations.

Barcode management

Reduce labor costs by implementing automated inventory tracking with barcodes. Automate product identification, and get extremely fast recognition and implementation of data.

Batch Traceability

The Batch Traceability module captures and records detailed information about the production process, materials used, and the movement of products within the supply chain.

Management Software designed for Flexible Packaging producers

HiFlow 4.0 for Flexible Packaging handles the complex needs and standards unique to the flexible packaging industry

Over 70 configurable modules

HiFlow’s system is modular – with over 70 modules, we can configure a tailor-made solution for your unique business. Find out more about your choices.

One central database

A centralized database collects information to a single location that can be accessed by all departments. Data integrity in your database has many advantages…

Production Scheduler

HiFlow’s Production Preparation and Production Planning systems get your job production plan up and running FAST so jobs move quickly into your plant and on to completion.

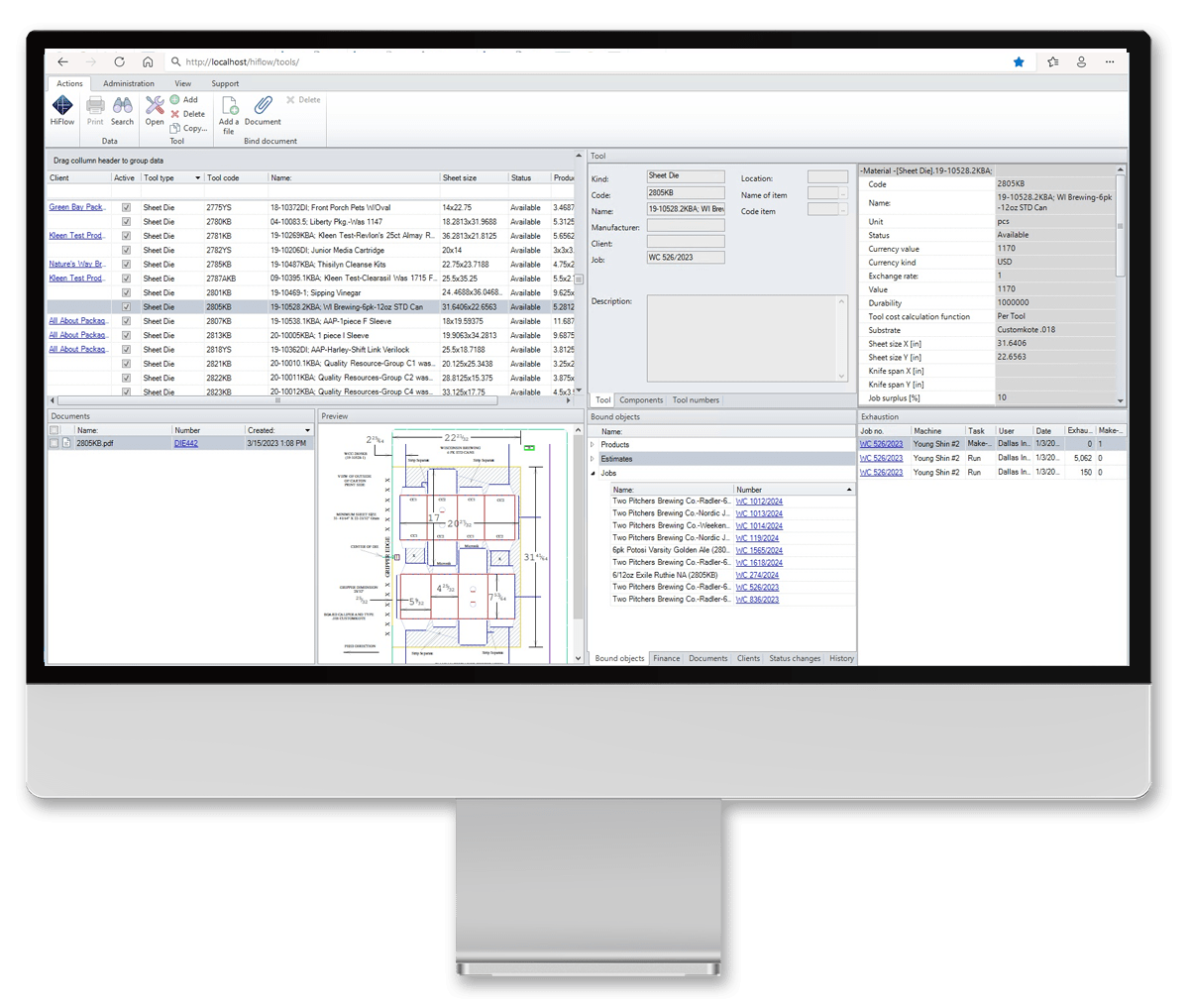

Manage all

your flexo tools.

A vast amount of information is available about a die/tool – all stored in one database. And accessible by estimating and production.

- Print Sleeves

- Anilox Rollers

- Flexo Plates

HiFlow’s Tools Management module offers comprehensive information on each tool:

- Durability of die (filled when adding new die)

- Exhaustion (how many impressions)

- Exhaustion % – compares exhaustion to durability

- Job & date of last use

Tools Management

Prevent downtime and reduce make ready times, remakes and labor costs. Organize your dies and tools with HiFlow.

MATERIAL AND TOOL AVAILABILITY

HiFlow’s Material and Tool Availability module creates real-time visibility into material and tool availability and increases speed of production. It minimizes errors in scheduling.

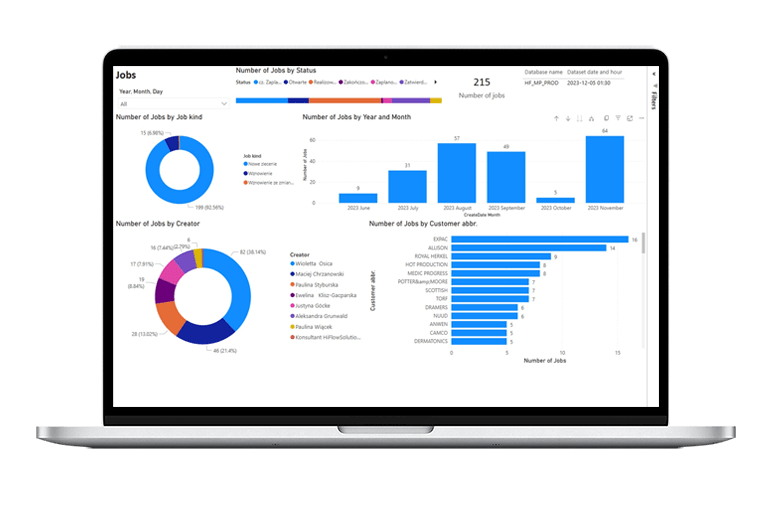

Reporting

By analyzing the performance results and comparing them to historical data, the Reporting module provides the necessary background for making the right decisions.

Business Intelligence

See complex data in a clear and understandable manner; analyze trends, identify patterns, and gain insights into key performance indicators (KPIs).

Data collection.

The key to Lean.

By collecting data from machines and the shop floor, flexible packaging producers can optimize production and minimize operational slowdowns and disruptions.

Create a leaner operation with data-driven decision-making.

- Ensure you are meeting production goals.

- Develop a maintenance program based on real-time notifications and machine conditions.

- Forecast accurately, get real time information on condition of flexo tools, reduce waste.

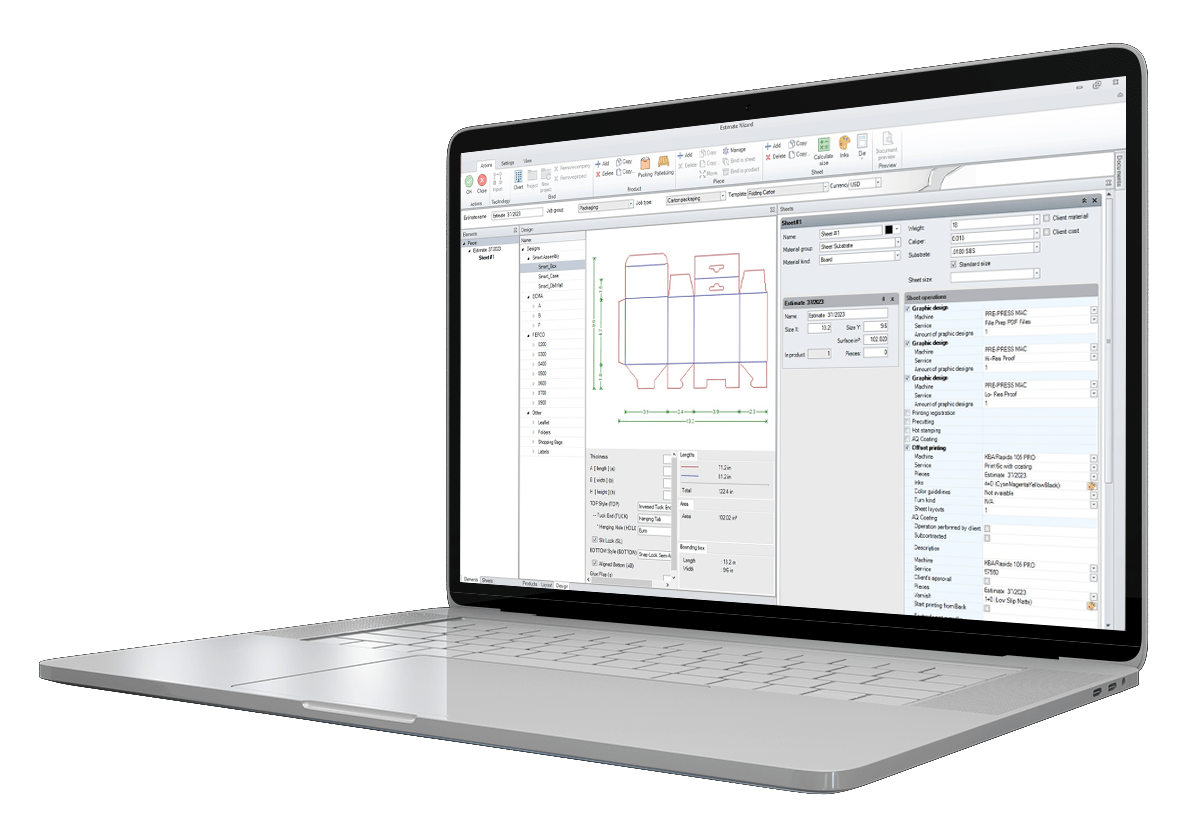

FAST estimating

and job creation.

Empower your estimators with a solution specialized for flexible packaging

- Custom product building by defining length, width, gusset

- Calculates multi-layer compounds in the extrusion step

- Defines number of tools and color changes

- Imposition module available to estimating

- Consideration of setup time (like slitting or sterilization) for all production steps

- Custom size and custom shape calculators

Estimating

Get jobs moving quickly by turning inquiries into quotes with just a few clicks. Then turn your entire estimate into a visual diagram of the entire production process.

Sales Planning

Determine the most profitable customers, and products and access predictive planning and sales forecasting.

Quote Generator

Automatically generate a professional-looking quote, complete with pricing details and a breakdown of costs.

Optimize your shop floor with a robust scheduling tool.

Production Scheduling

Using smart algorithms, HiFlow’s scheduler enhances your scheduling process and ensures that work is completed on time and resources are optimally utilized.

Schedule Viewing

Display real-time production scheduling data on large monitors on your shop floor! View job priority, due date, and job numbers, by machine or department.

Shop Floor Monitor

The Shop Floor Monitor module allows any shop floor worker to clearly see all the data about current jobs and job order progress at each stage of production.

Take advantage of HiFlow’s machine connectivity and real-time data to optimize production and plant operations.

- Account for ink changeouts, equipment set-ups, different cure times.

- Reschedule dynamically by dragging & dropping job orders and operations in HiFlow’s Production Scheduling module.

- Deliver optimal machine and process utilization.

- Avoid downtime waiting for materials or tools.

- Rapidly respond to unanticipated events.

Audit & Regulatory Compliance.

ISO, FDA, USDA GMP, EU MDR

Ensure compliance with traceability through HiFLow’s modules, from receipt of raw materials to production and shipping of finished goods.

- Product Versioning

- Serialization

- Electronic Signatures

- Audit Reports

- Product Inspections

- Roll to Roll Tracking

HAVE MORE QUESTIONS?

The Comprehensive

Q&A to HiFlow 4.0

- What is an MIS for packaging?

- How do MIS and shop floor data collection (MES) work together?

- What’s the difference between HiFlow and ‘out of the box’ ERP systems?

- I am a medium-sized commercial shop expanding into lexible packaging. Can you help me?

- Can I configure the solution to meet my future needs?

- I already have prepress software (ESKO) that the team loves. Can you integrate with it?

- How long is the implementation period? Is your staff available to us throughout this period and beyond?

You are not just a customer. We partner with you during implementation and beyond to help you achieve your business and production goals.

Read about how companies like yours have increased efficiency, reduced labor costs, and leveled up in the marketplace.

An ERP solution for flexible packaging. Find out more

Schedule a walkthrough of our software with our technical staff that is customized to meet the unique needs of YOUR company.

Find out how our demos are structured and what to expect.

Follow us on LinkedIn to stay current on the latest industry trends and new developments at HiFlow.