ERP/MIS for Folding Carton Manufacturers

Control costs, accelerate throughput

MIS Software With an end-to-end management system designed for FOLDING CARTON companies

Delivering

automation,

connectivity and insight to folding carton printers and converters

Over 70 configurable modules

With HiFlow, you can be assured that the software you buy is the perfect fit. With over 70 modules, we can configure a tailor-made solution for your unique business.

Visual Product Workflow

HiFlow’s Job Production Workflow diagram illustrates the entire job on one screen. Materials, machines, people, documents, tools and any other part or process is represented.

Warehouse Optimization

HiFlow’s unique WMS consists of modules that manage your warehouse processes efficiently and effectively, even when you have multiple locations.

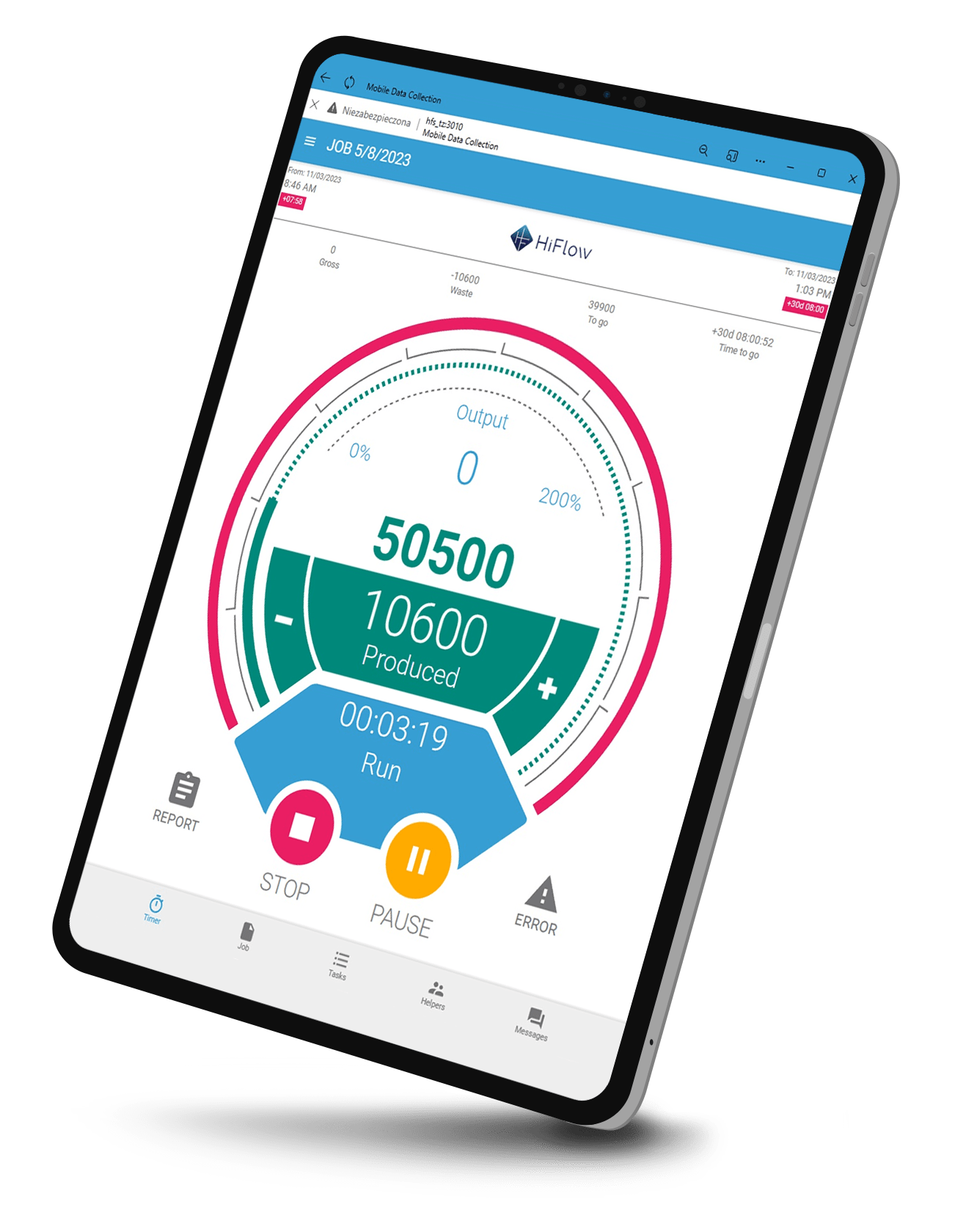

Shop Floor Data Collection

The Shop Floor Data Collection module is Smart Factory in action. With the real-time data collection, gain increased visibility into the entire production process from end to end.

Imposition module built-in

What was once a labor-intensive process is now streamlined and automated with HiFlow 4.0. Give your estimators the tools to optimally lay-out jobs.

Tools Management

Prevent downtime, and reduce make ready times, remakes and labor costs. Organize your dies and tools with HiFlow.

Imposition Built in.

When estimating is dependent on the CAD department for generating a layout plan, lead time becomes a big factor.

Give your estimators the tools to layout jobs in an optimum way to minimize costs and increase throughput. By consolidating the work with estimators, there is less back and forth, less likely opportunity for error, and huge time savings.

HiFlow offers completely customized box design and imposition tools for printers and converters of all sizes.

Packaging Design

Reduce the time estimators spend calculating materials. Using FEFCO and ECMA libraries, the Packaging Design module allows dynamic creation of packaging designs.

Packaging Imposition

Get quotes out quickly! Arrange and position multiple images on a single sheet or substrate to optimize printing and production efficiency.

Dies & tools meet

smart automation.

Prevent downtime and reduce make ready times, remakes and labor costs. Organize your dies and tools with HiFlow.

- Tool location, usage and status tracking.

- Prevention of unmaintained tool usage.

- Complete history of tool usage from purchase to exhaustion.

Control and visualize

operations in real time

With HiFlow’s customizable Dashboards, leverage data to produce reports from your production, processes and machines. Unlock data insights to support important business decisions.

REPORTING

Create impactful, visual reports with a unified, scalable platform that connects to all data sources.

Business Intelligence

Visualize any data, and seamlessly infuse the visuals into the apps you use every day. Personalize dashboards with the KPIs that are important for each of your personnel to be monitoring.

Transform operations with machine connectivity through HiFlow’s MES

Transform operations with machine connectivity through HiFlow’s shop floor data collection tools (MES)

With HiFlow’s interconnected data management modules, track KPIs in real time. Deep data from sources including people, machines, devices, integrated ERPs, and shop floor data collection (MES) — you can access from anywhere.

WHAT IS MES?

Your plant generates hundreds of data points every millisecond – what happened in the past, what’s happening now, and what will happen next. An MES, also referred to as shop floor data collection, connects the dots.

Direct Machine Interface

Having a DMI (Direct Machine Interface) is key to unlocking the power of Industry 4.0 for your packaging business. Collect deep data generated by machines, into a centralized networked system.

See clearly into warehouse and inventory.

HiFlow’s Warehouse Management System (WMS) modules offer clear views into inventory levels and warehouse operations. By automating your warehouse management processes you improve accuracy, manage orders, and check inventory.

inventory of materials

Know exactly when to replenish your warehouse, stay ahead of customer needs, and predict upcoming labor needs based on demand. Track every aspect of your material needs…

Multi-Location Inventory Management

One single, accurate, real-time source of data and control gives companies with multiple locations a leg up on the competition…

HAVE MORE QUESTIONS?

The Comprehensive

Q&A to HiFlow 4.0

- What is an MIS for packaging?

- How do MIS and shop floor data collection (MES) work together?

- What’s the difference between HiFlow and ‘out of the box’ ERP systems?

- I am a medium-sized commercial shop expanding into folding carton. Can you help me?

- Can I configure the solution to meet my future needs?

- I already have prepress software (ESKO) that the team loves. Can you integrate with it?

- How long is the implementation period? Is your staff available to us throughout this period and beyond?

You are not just a customer. We partner with you during implementation and beyond to help you achieve your business and production goals.

Read about how companies like yours have increased efficiency, reduced labor costs, and leveled up in the marketplace.

MIS for Folding Carton. Find out more

Schedule a walkthrough of our software with our technical staff that is customized around the unique needs of YOUR company.

Find out how our demos are structured and what to expect.

Follow us on LinkedIn to stay current on the latest industry trends and new developments at HiFlow.