ERP/MIS for Label

and Tags Converters

Create visibility in your label production lifecycle

HiFlow provides an MIS solution specifically designed for end-to-end management of label and tag converting.

Automation, connectivity and insight to label converters

Over 70 configurable modules

HiFlow’s system is modular – with over 70 modules, we can configure a tailor-made solution for your unique business. Find out more about your choices.

One central database

A centralized database collects information to a single location that can be accessed by all departments. Data integrity in your database has many advantages…

Warehouse Optimization

HiFlow’s unique system consists of modules that manage your warehouse processes efficiently and effectively, even when you have multiple locations.

Barcode Solution

HiFlow automates inventory systems with a robust Barcode module. Reduce labor costs by implementing automated inventory tracking with barcodes.

Quality ControL

Real-time tracking of equipment and raw material availability. Data relative to non-conformities, tests, and inspections can also be tracked to help ensure compliance with industry regulatory mandates.

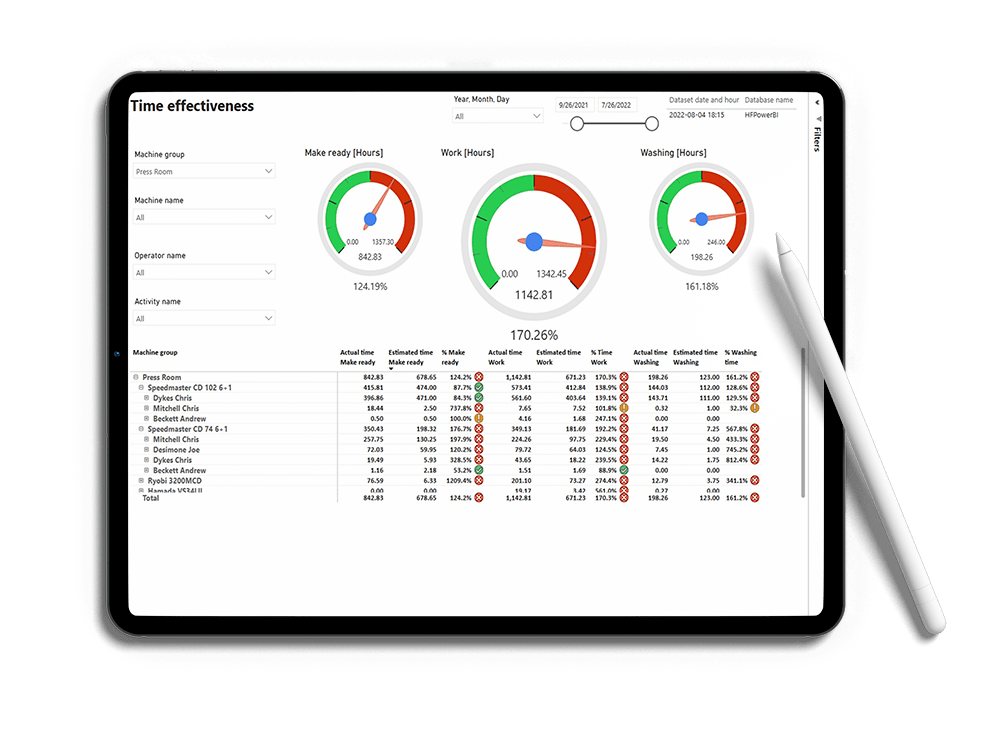

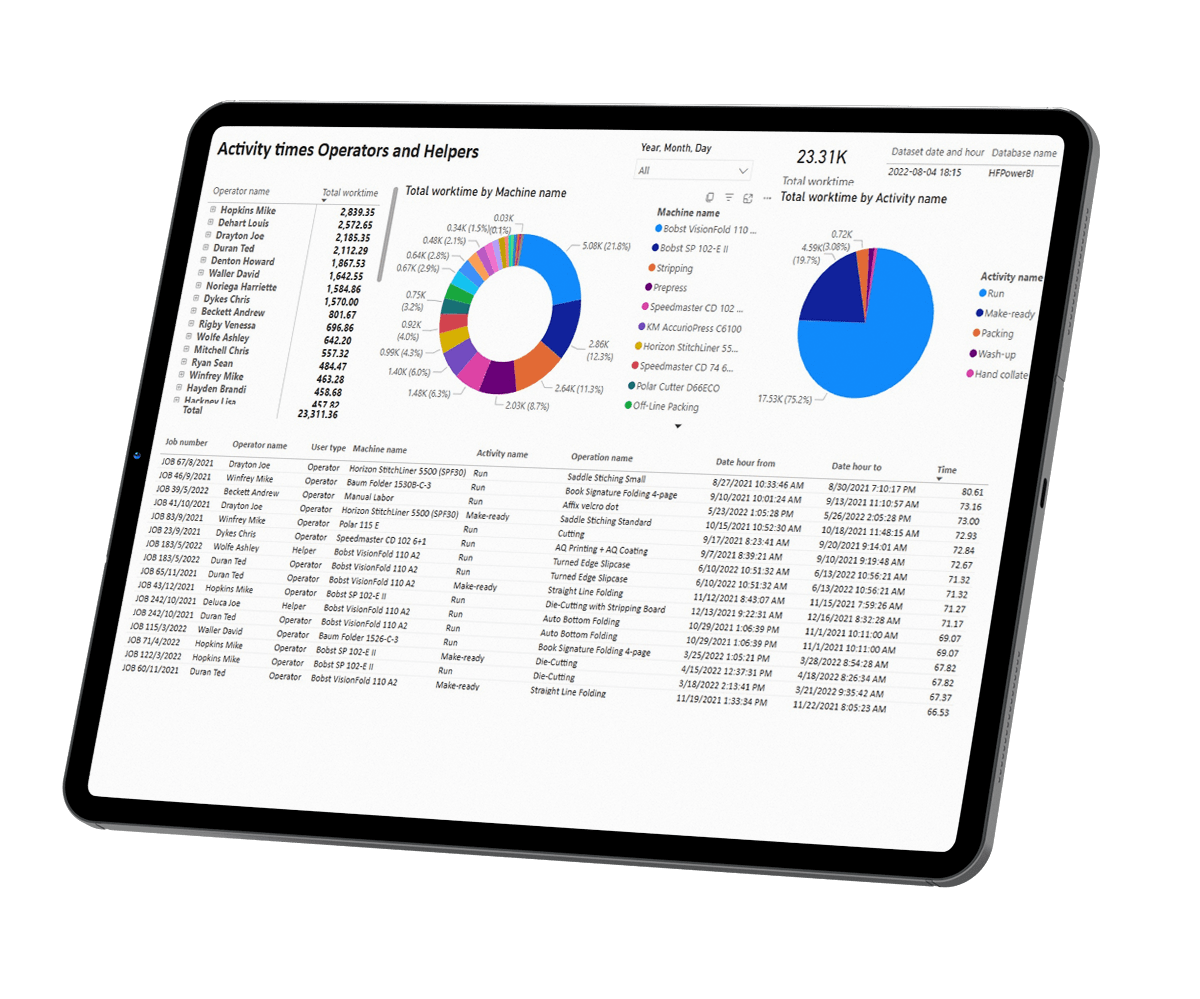

Control and visualize label operations in real time

With HiFlow’s customizable Dashboards, leverage data to produce reports from production, processes and machines. Unlock insights that support important business decisions and future forward strategies.

Product Inspection

Ensure traceability and accountability, and provide a comprehensive audit trail for compliance purposes, customer inquiries, and quality control assessments.

Batch Traceability

The Batch Traceability module captures and records detailed information about the production process, materials used, and the movement of products within the supply chain.

Material Inspection

Manage incoming, pre-shipment, and production inspections while mitigating compliance risks. Give quality control teams better visibility on inspections.

Tools for complying

with Regulatory Environments

HiFlow offers complete traceability for each batch used in the production process (raw material, semi-finished product, finished product). The tests of raw materials, semi-finished products and finished products are fully configurable, and can be adapted to various regulatory agencies such as FDA, USDA, or EU MDR. This includes:

- Product Versioning

- Serialization

- Inventory Tracking

- Electronic Signatures

- Inspections and Quality Control

- Auditing & Reporting

- Production Tracking

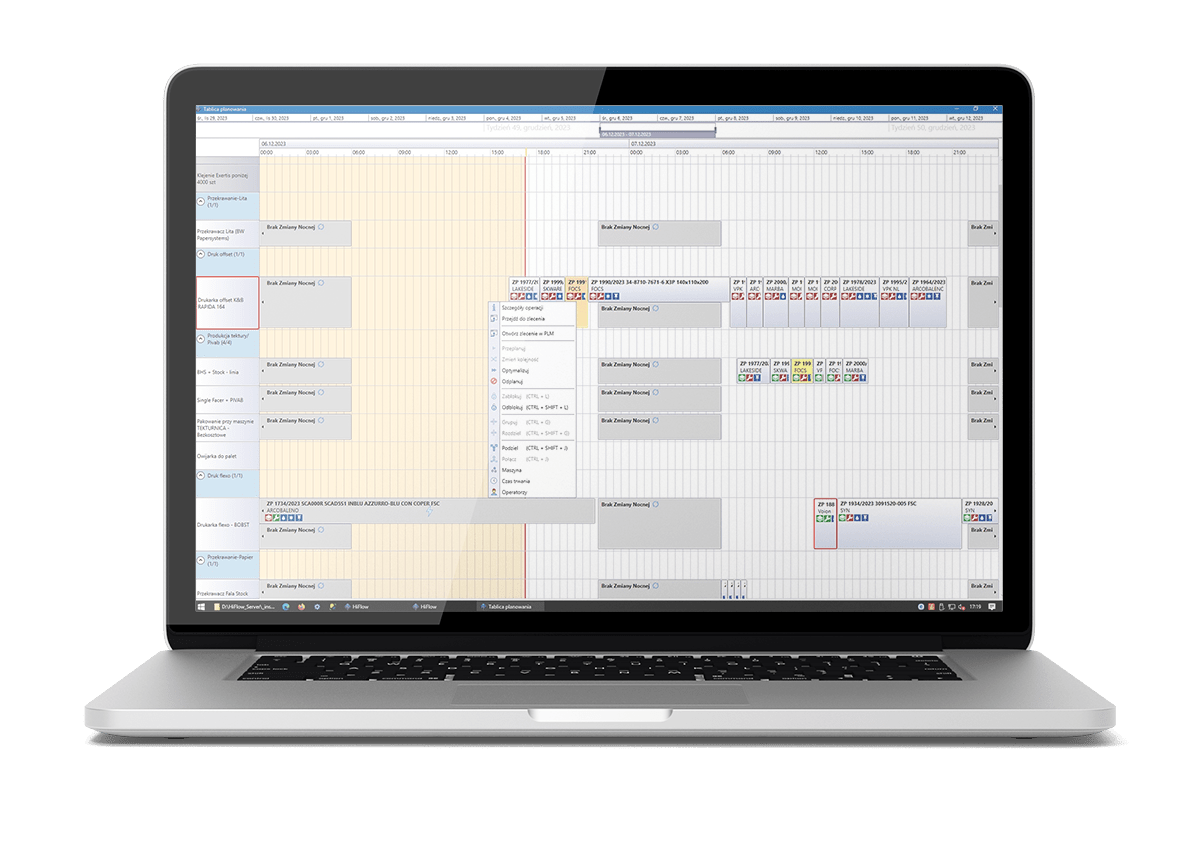

Increase label production speed with automation

Accelerate the speed of estimating. Turn an inquiry into an estimate into a job in just a few clicks.

Accelerate scheduling. Smart algorithms automatically create & optimize plans to maximize the use of your plant.

Boost production rates with real-time visibility. Monitor the entire production flow – jobs, workers, materials, machines, waste, time, costs, in one plant or across multiple plants.

Benefit from a clear view into warehouse and inventory actions and status.

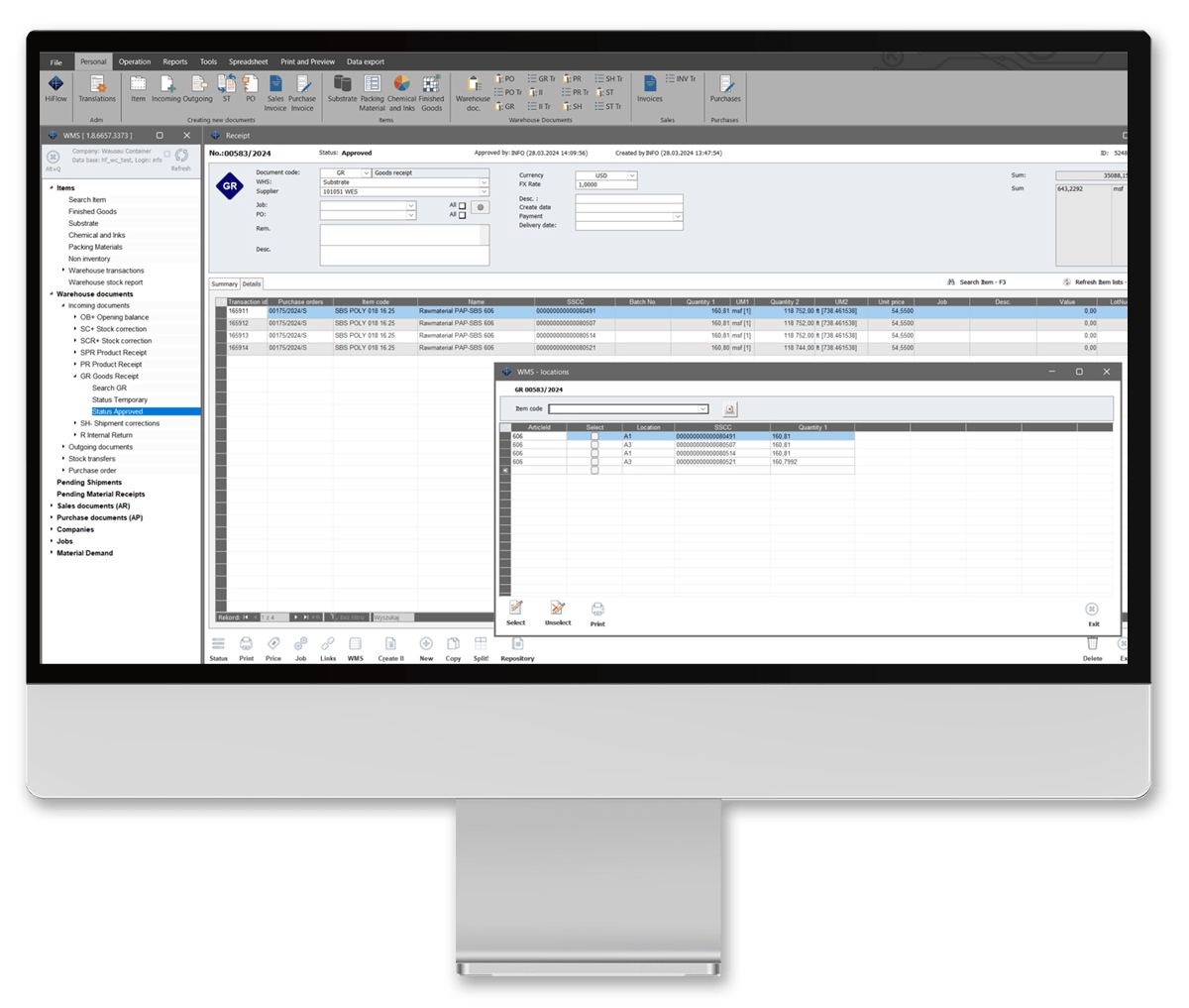

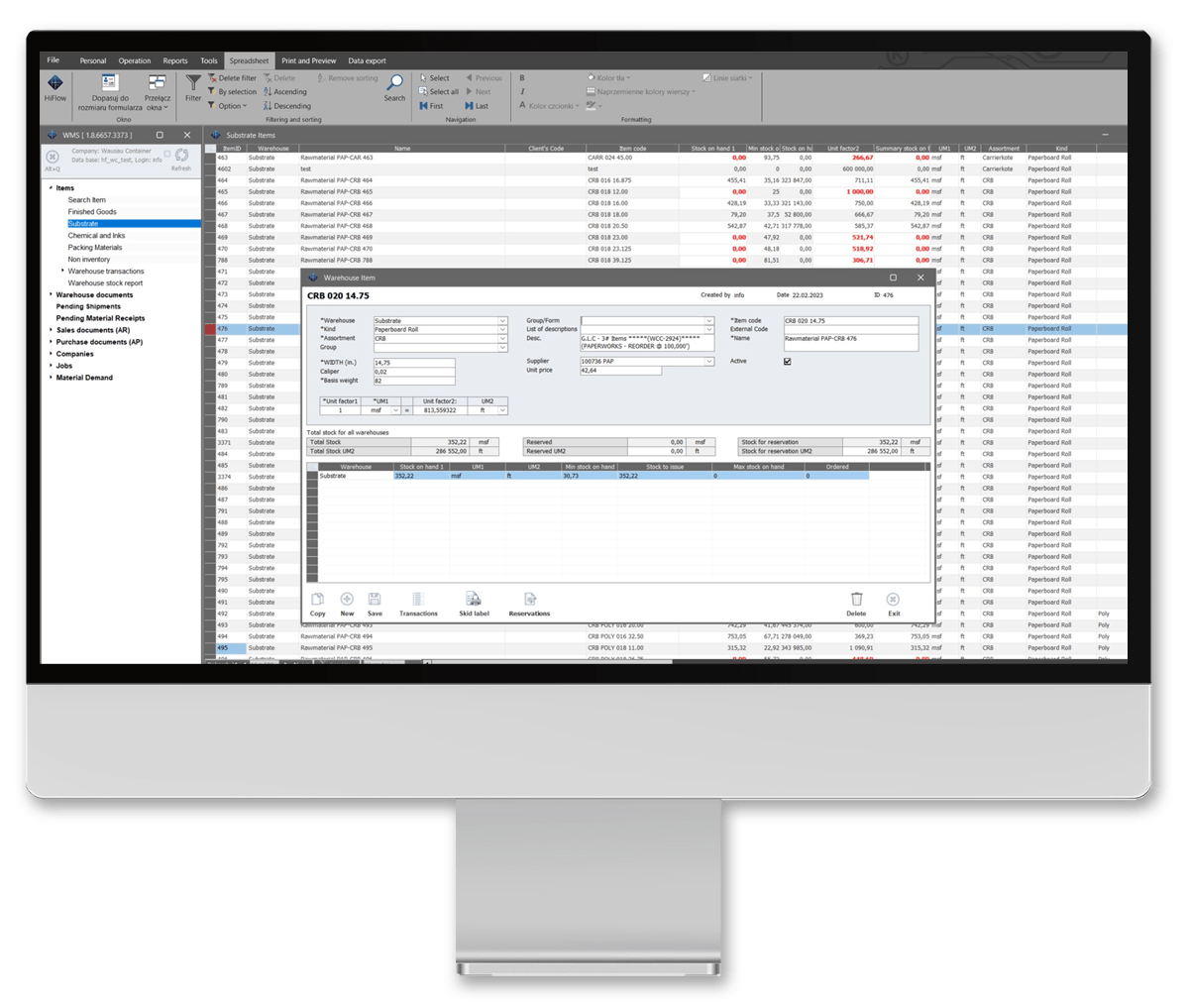

HiFlow’s Warehouse Management Solution (WMS) modules offer clear views into inventory levels and warehouse operations. By automating your warehouse management processes, you can trace raw materials back to their source, ensuring integrity.

Inventory of Materials

By leveraging an Inventory of Materials module, packaging businesses can streamline their inventory management processes. Make real-time data-driven decisions regarding inventory control and optimization.

Inventory Locations Management

Manage inventories with a six-level system that enables efficient inventory organization and retrieval. Track physical locations where inventory items are stored in real time.

Connect all your locations

Many label companies have more than one plant location. Or a company has been acquired and plants have been consolidated. This can result in many different label software versions in use.

In decentralized operations, each facility may develop its own systems that provide essential data. This can introduce inaccuracies that reduce data quality, often resulting in unnecessary complexities, errors, and noncompliance. And it makes it harder to manage the business in a holistic manner.

HiFlow’s centralized business, production, and warehouse management solutions, these challenges are easier to address, providing a total view of the business, regardless of how many different locations or systems are in use.

A centralized label management system means control, consistency and compliance

A single source of data, secure job and financial data, audit trail capture, job and document saving from a single site — in your headquarters — can improve labeling accuracy, system security and regulatory compliance.

HAVE MORE QUESTIONS?

The Comprehensive

Q&A to HiFlow 4.0

- What is an MIS for packaging?

- How do MIS and shop floor data collection (MES) work together?

- What’s the difference between HiFlow and ‘out of the box’ ERP systems?

- I am a medium-sized commercial shop expanding into tags and labels. Can you help me?

- Can I configure the solution to meet my future needs?

- I already have prepress software (ESKO) that the team loves. Can you integrate with it?

- How long is the implementation period? Is your staff available to us throughout this period and beyond?

You are not just a customer. We partner with you during implementation and beyond to help you achieve your business and production goals.

Read about how companies like yours have increased efficiency, reduced labor costs, and leveled up in the marketplace.

HiFlow has an MIS solution tuned to the needs of label and tag manufacturers. Find out more

Schedule a walkthrough of our software with our technical staff that is customized to the unique needs of YOUR company.

Find out how our demos are structured and what to expect.

Follow us on LinkedIn to stay current on the latest industry trends and new developments at HiFlow.