It’s a new era. The conversation around AI is shifting rapidly — from “Should we explore AI?” to “What’s our plan to implement it?”

Packaging manufacturers are entering a defining decade — one where efficiency, precision, and data will separate leaders from laggards. Artificial intelligence (AI) is no longer a futuristic concept, it is looked at as a way to both quickly receive ROI and future proof operations.

This article provides an actionable roadmap for manufacturers ready to leverage AI functionality across their operations — with examples inspired by real-world ERP/MIS/MES modules that are already transforming how packaging businesses operate.

If you are ready to adopt AI into your operations, this article is for you.

Define the “Why” — The Strategic Purpose Behind AI

Before diving into AI adoption, packaging manufacturers must define the “why.”

AI isn’t a cure-all. It’s a set of intelligent tools designed to augment existing processes — not replace them overnight.

For packaging converters, the primary business drivers often include:

Reducing manual data entry and repetitive administrative work

Improving estimating speed and accuracy

Optimizing production schedules for faster throughput

Reducing errors in purchase order and delivery processing

Enhancing traceability and decision-making through analytics

The most successful companies begin by identifying one or two business-critical areas — often the most time-consuming manual processes — and applying AI functionality there first.

Examine Your Operation’s Workflows

AI delivers the most value in structured environments. Before implementation, take a look at :

- Current workflows — from order intake to production to shipping.

- Data sources — ensuring item codes, supplier lists, and machine performance data are clean, standardized, and accessible.

- Integration points — between ERP/MIS systems, scheduling software, and shop floor data collection.

A strong data foundation enables AI to “learn” faster and make more accurate predictions. Without clean data, even the most advanced algorithms can fail to deliver meaningful results.

Start AI Implementation with Low-Risk, High-Return Processes

Packaging plants should begin AI integration in low-risk, repetitive areas where ROI is easy to measure and can be achieved quickly. These are often administrative bottlenecks.

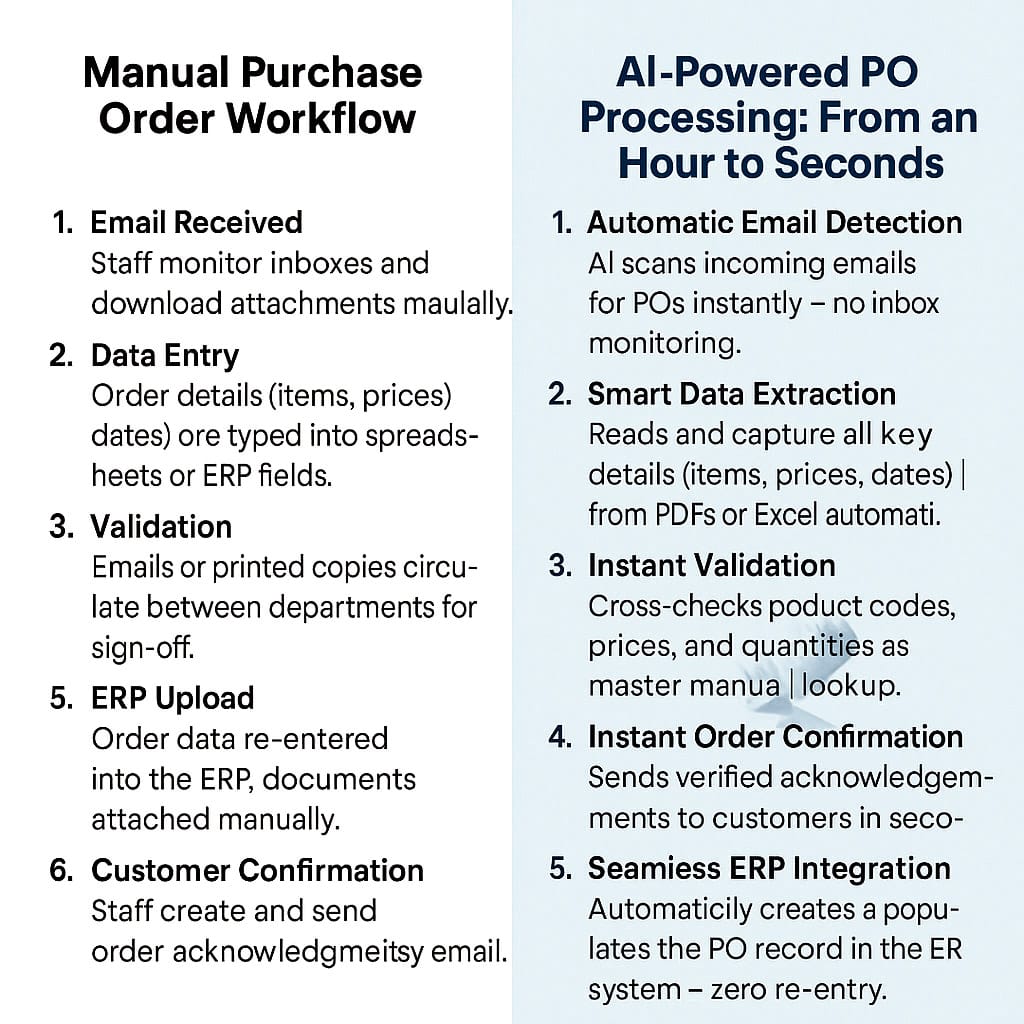

Example 1: AI-Powered Purchase Order Processing

Traditionally, PO management involves manually opening emails, downloading PDFs, keying data into ERP systems, and cross-checking for errors. AI now automates this entirely. Intelligent document parsing reads incoming POs, extracts key data fields, validates them against the product database, and registers them in the ERP system — in seconds. The benefits are measurable: faster turnaround times, fewer manual errors, and real-time readiness for production scheduling.

Integrate Predictive Intelligence into Production

Once administrative tasks are streamlined, the next frontier is operational optimization.

Example 2: AI-Enhanced Production Scheduling

AI-driven scheduling uses machine learning to analyze hundreds of data points — including job types, material availability, machine speed, and operator performance — to dynamically optimize production sequences. AI analyzes a wide range of variables — job priorities, material availability, machine status, operator capacity, and due dates — to generate and continuously update the optimal production schedule.

For example, a folding carton converter runs multiple presses and finishing lines with varying capacities.

Traditionally, rescheduling after a press malfunction could take hours of manual recalculation.

With AI-powered scheduling:

The system detects the downtime event automatically.

It rebalances production by reassigning jobs across machines.

Operators receive updated digital job tickets instantly.

Management dashboards update KPIs in real time.

The result: a seamless adjustment process that prevents disruption from rippling through the plant.

AI Functionality in Supply Chain & Finance

Once AI delivers results in production and planning, the next step is expanding its reach across the value chain.

Example 4: AI in Supplier Delivery & Price List Management

AI can read supplier emails, extract shipping or pricing data, and automatically update inventory or cost records — eliminating manual reconciliation. The system identifies discrepancies, validates against past purchase history, and triggers alerts when price changes exceed tolerance levels.

This level of automation reduces procurement workload and gives financial teams real-time visibility into cost fluctuations.

Example 5: AI-Powered Accounts Payable Processing

AI transforms invoice handling by extracting and validating data from PDFs or emails and automatically registering it in the ERP system. No manual keying. No missed entries. No delays in payment approval.

Finance teams can process more invoices per hour while maintaining complete audit trails — improving both accuracy and supplier relationships.

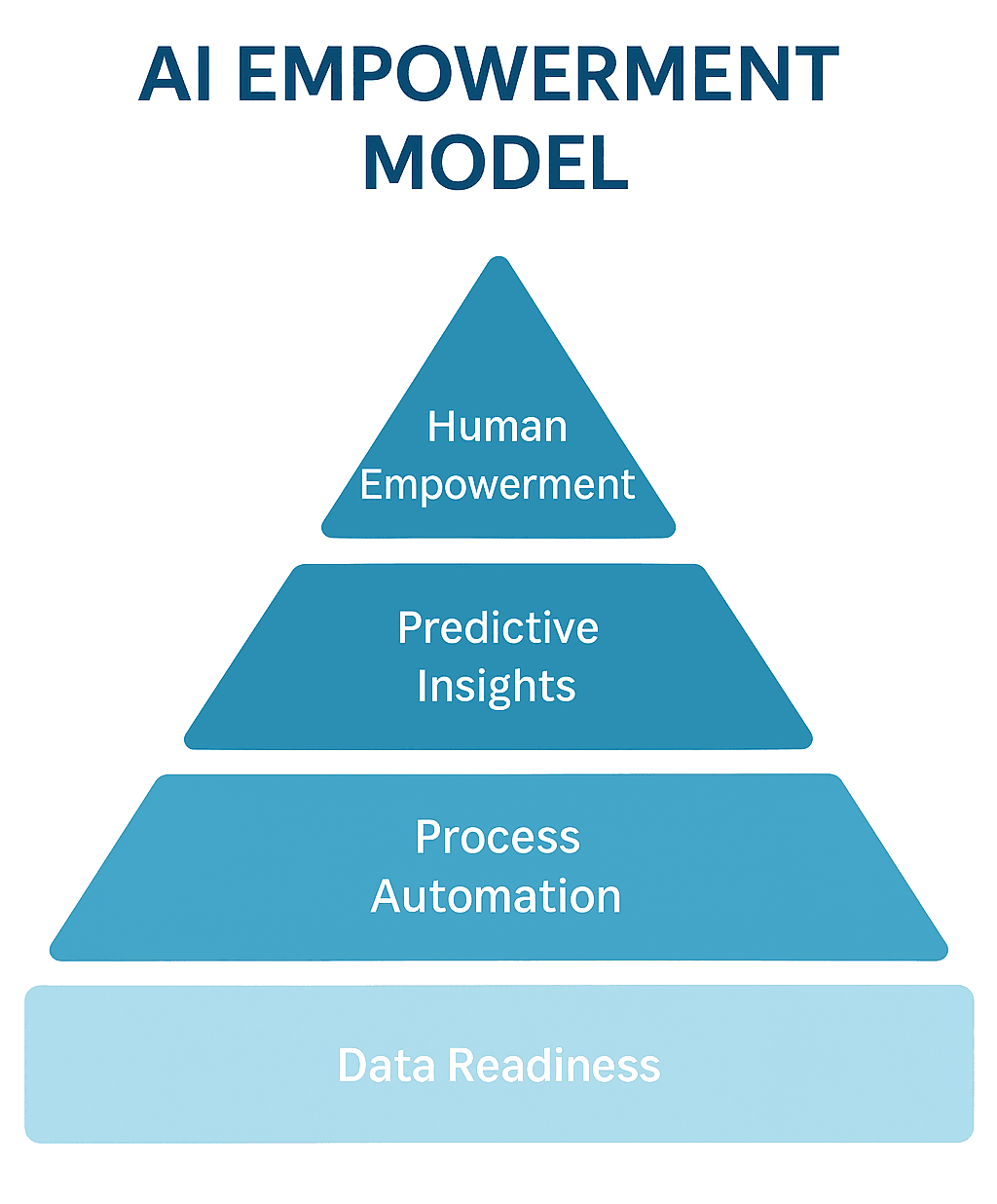

Empower People, Not Replace Them

AI adoption succeeds when it enhances human performance, not undermines it. Training employees to trust AI insights is as important as implementing the technology itself.

Involve users early in the design process.

Provide hands-on workshops to show how AI outputs improve accuracy and efficiency.

Encourage feedback and iterative improvements.

When employees see AI as an enabler — one that reduces tedious work and allows them to focus on problem-solving — adoption accelerates naturally.

Build a Measurable AI ROI Framework

Every AI investment must prove its value. Most packaging manufacturers implementing AI within their ERP or MIS systems report a positive return on investment within 6 to 12 months. The gains are typically realized through three primary drivers:

- The elimination of manual processes that previously consumed hours of administrative time.

- The acceleration of production flow and scheduling accuracy enabled by predictive algorithms.

- The reduction of costly mistakes through real-time data validation and automated decision-making.

Plan for Scalability — From AI Pilot to Smart Plant

AI implementation isn’t a one-time upgrade — it’s an evolution. The most successful manufacturers design AI roadmaps that scale across departments:

Phase 1: Administrative automation (POs, invoices, data collection)

Phase 2: Operational optimization (scheduling, costing, planning)

Phase 3: Predictive insights and analytics

Phase 4: Enterprise-wide intelligence (integrating suppliers, logistics, and customers)

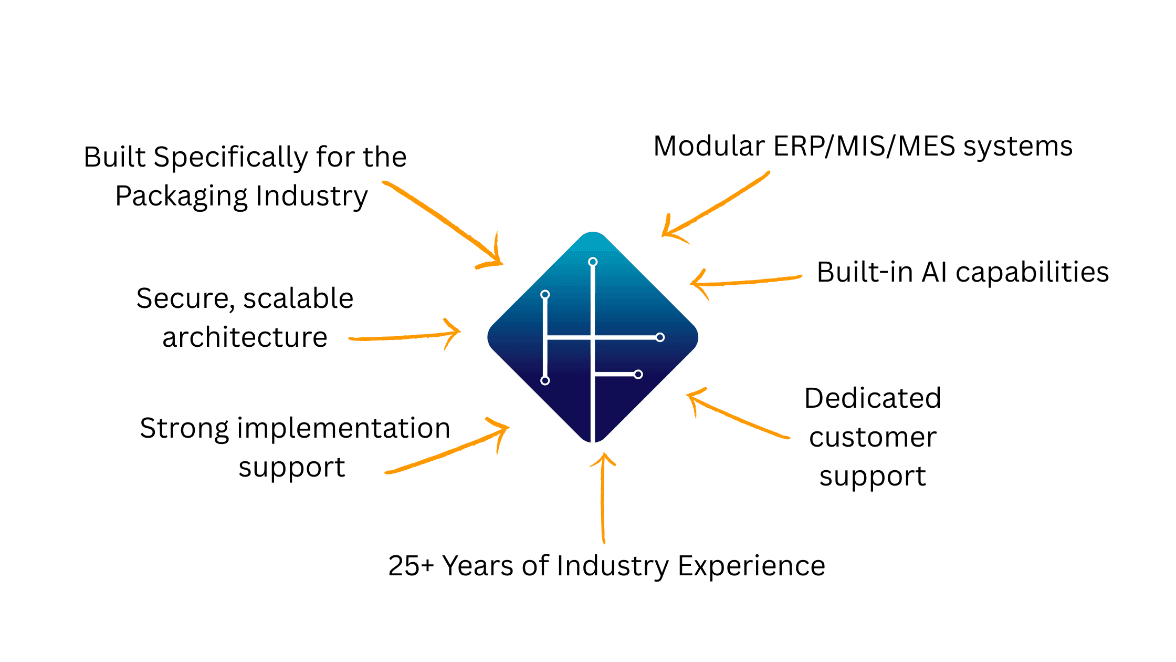

Partner with the Right Technology Provider

AI in packaging manufacturing isn’t plug-and-play — it requires the right partner who understands both technology and production realities. Success depends on working with software providers who:

- Know packaging operations — from flexo and label converters to folding carton and corrugated.

- Offer modular ERP/MIS/MES systems with built-in AI capabilities that scale with your business.

- Provide strong implementation support — including data preparation, governance, and user training to ensure smooth adoption.

HiFlow Solutions delivers this balance of expertise and innovation. Its AI-powered ERP platform helps packaging converters:

- Integrate AI seamlessly into estimating, scheduling, PO automation, and analytics — without workflow disruption.

- Leverage secure, scalable architecture built on Microsoft technology.

- Future-proof operations with ongoing AI enhancements and dedicated customer support.

AI Implementation: The Future Is Intelligent and Incremental

For decades, packaging plants have been optimized through lean principles, automation, and ERP systems. AI is the next leap — not a revolution that replaces people, but an evolution that enhances decision-making and accelerates operational processes.

The future packaging leader will be the company that combines human expertise with intelligent automation — building a connected, adaptive, and data-driven enterprise.

The roadmap is clear: define your vision, build data foundations, start small, measure results, and scale with confidence. When done right, AI isn’t just an upgrade — it’s the foundation of a smarter, faster, and more resilient packaging operation for today’s market, and the future…

Additional articles you might find valuable

Bridging the Gap: Leveraging an ERP/MIS to Mitigate Skilled Labor Shortages

SUMMARY The skilled labor shortage has become a significant challenge across various industries, with sectors like manufacturing, logistics, and packaging feeling the impact most acutely. As the demand for skilled labor continues to outpace supply, organizations are...

Shop Floor Scheduling: Are You Getting the Most out of Your Plant’s Production Capacity?

SUMMARY Summary: SEMrush data from 2024 shows that companies integrating advanced scheduling technologies experience a 25% increase in production efficiency. Getting the most out of your plant’s capacity means implementing a robust ERP that helps plan, execute, and...

Seeing is Believing: Exploring HiFlow’s Highly Visual Workflow

SUMMARY Sometimes it can be difficult to quickly get to a full 360-degree view of the converter’s operation, including both production and business elements. That’s why HiFlow developers have placed a strong focus on developing a highly visual representation of a...