Fano

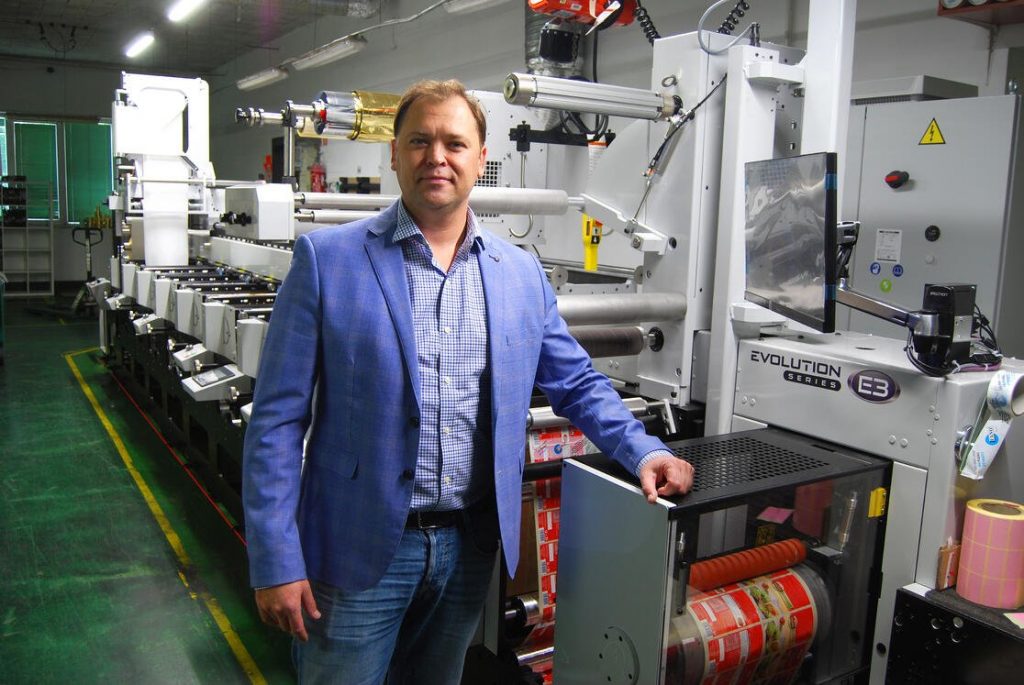

FANO is a family owned label printing and flexible packaging company that has been in the printing industry market since

1995, when it was an offset printer. Since then, FANO’s successes led them to greatly expand their services–adding labels and packaging to their commercial printing business. Today, FANO provides self-adhesive labels, flexible packaging, shrink sleeves, stationery, folding, stamping, laminates, embossing and roll-to-roll films to its customers.

We were constantly working at a disadvantage before HiFlow

Legacy methods replaced

At the start of their business, FANO used simple Excel spreadsheets instead of a software system. The company then turned to its IT team to develop a system, and soon thereafter another version, slightly better, but almost equally a simple, nonintegrated system that only provided calculations, pricing and a simple scheduling plan.

This system wasn’t linked to production, financial or accounting programs and had no modules for carrying out post-production analysis. In other words, according to FANO’s vice president, Bolesław Jasinowicz, “We were constantly working at a disadvantage.”

The number of errors in our company has certainly

decreased. By automating processes, defining the

various work parameters in the system, we have made

significant progress in this respect.

Linking systems, creating efficiency

Unlike their previous system, HiFlow is primarily a friendly, transparent, multi-window interface that links business systems and provides instant access to current information at different levels of detail. An essential feature of the system for Fano is that the most important documents (calculations, estimates, quotes, production plan, etc.) are systematically linked. This enables FANO to work smoothly and flawlessly at all stages of estimating, planning, scheduling, production, shop floor data–all the way to invoice.

Integration = faster workflow

The system suggests solutions, prevents mistakes, and facilitates FANO’s workflow. And by integrating all information into a single database, the system enables efficient day-to-day process control, optimizing production. For example, the rapid startup of product workflow translates into production repeatability, which translates into cost savings. Estimating, quote, product order–all produce shop floor data that is accurate and timely.

I love the modern business

intelligence provided by

the system.

more

It gives us

unrestricted access to

information in real time

and offers us the

possibility of making faster

and more optimal

decisions

More visible data

Secondly, everyone in the company is linked to the job information at all levels—it makes managing products and orders very easy. An impressive example of visibility is the preview of the production plan, HiFlow’s workflow diagram. Planning and scheduling, as well as customer service, can easily see the whole of the job. They are able to immediately inform the customer of the earliest possible date of delivery of products and services. Ultimately, this promotes greater customer satisfaction.

The Benefits of Partnering

with HiFlow Solutions

We implement – fast. The HiFlow system combines MIS and MES software with easy ERP integration.

We fill your ERP gaps. By optimizing ERP systems with MIS and MES features required for packaging and label printing.

We create automated environments. With seamless connections from order intake to shipping and invoicing.

We feed you data. With insights from real time, critical information from your production shop floor, personnel, and equipment.

We let you see. From smart scheduling to nested layouts to workflow diagrams, instantly see where you stand within the job.