The strategic pressures shaping packaging operations — and why AI-driven automation will define next year’s winners.

As 2025 closes, packaging CEOs face a perfect storm—market volatility, tariff swings, workforce shortages, substrate price uncertainty, and accelerating AI adoption are converging into a defining moment for the industry.

One theme is clear: 2026 will reward companies that modernize their organizations—and punish those that don’t.

Drawing on insights from Deloitte, McKinsey, KPMG, PMMI, and top industry analysts, this article uncovers the forces packaging CEOs can’t afford to ignore in the year ahead.

1. Supply Chain: Still an issue in 2026

Tariff swings in 2025 forced converters to recalculate everything. But 2026 won’t bring stability—expect continued fragmentation across paper, paperboard, inks and aluminum substrates. Fastmarkets RISI projects a $50/ton kraftliner price increase in early 2026, and another $40/ton in 2027. New record-high premiums on aluminum imports surged to 88.10 cents per lb (approximately US$1,942 per metric ton) as of early November.

Yet the challenge isn’t just higher costs and tariffs—it’s unpredictability that makes accurate quoting nearly impossible.

How Modern ERP Systems Help: ERP platforms now integrate real-time supplier pricing feeds using AI to automate cost updates across the entire system. When a substrate price changes, the system automatically recalculates affected quotes, open orders, and inventory valuations—eliminating the lag between market shifts and internal pricing accuracy.

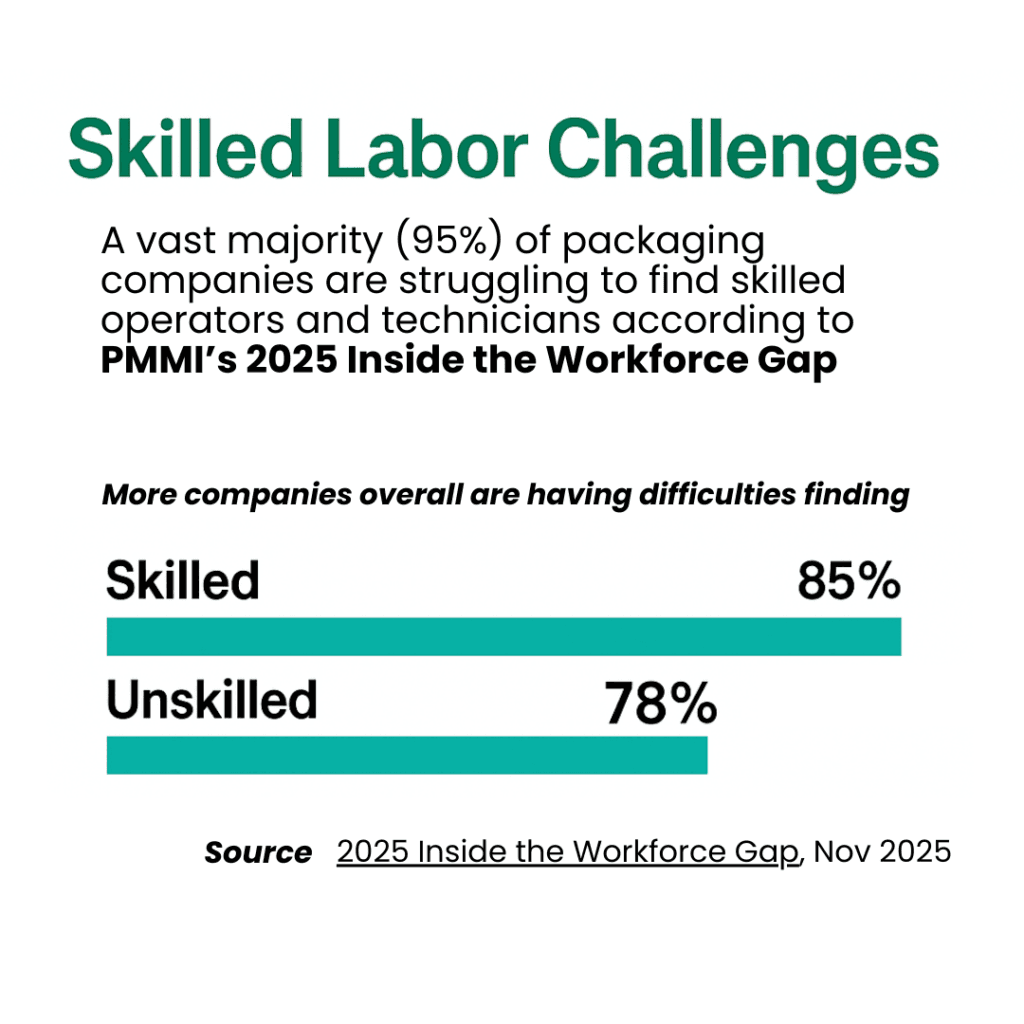

2. Technical Talent Crisis Grows Critical for Packaging CEOs

When experienced staff retire or leave, they often take undocumented “tribal knowledge” with them. The knowledge walking out the door—in estimating, prepress, planning, die engineering, and order entry—can’t be replaced fast enough. This is why AI-enabled automation shifted from optional to an essential asset for packaging CEOs.

When experienced staff retire or leave, they often take undocumented “tribal knowledge” with them. The knowledge walking out the door—in estimating, prepress, planning, die engineering, and order entry—can’t be replaced fast enough. This is why AI-enabled automation shifted from optional to an essential asset for packaging CEOs.

How Modern ERP Systems Help: Advanced ERP platforms capture institutional knowledge through rules-based estimating engines that codify decades of pricing expertise. When a veteran estimator retires, their decision logic—substrate selections, waste factors, setup times, tooling requirements—remains embedded in the system. Automated scheduling algorithms handle the complex optimization previously requiring experienced planners, while digital job tickets and standard operating procedures preserve prepress knowledge that would otherwise disappear.

3. Margins Under Siege

Brand owners demand cost cuts while expecting more SKUs, shorter runs, and faster turnarounds. Meanwhile, material costs climb and labor expenses soar. Traditional levers—raising prices, cutting labor, reducing quality—all fail in this environment. Efficiency is the only margin left.

How Modern ERP Systems Help: Comprehensive ERP platforms eliminate margin-eroding inefficiencies through connected workflows. Automated estimating reduces quote generation time from hours to minutes. Real-time job costing compares estimated versus actual costs on every order, flagging margin leaks immediately. Automated material tracking prevents over-ordering and waste, while integrated financial systems provide instant visibility into true job profitability.

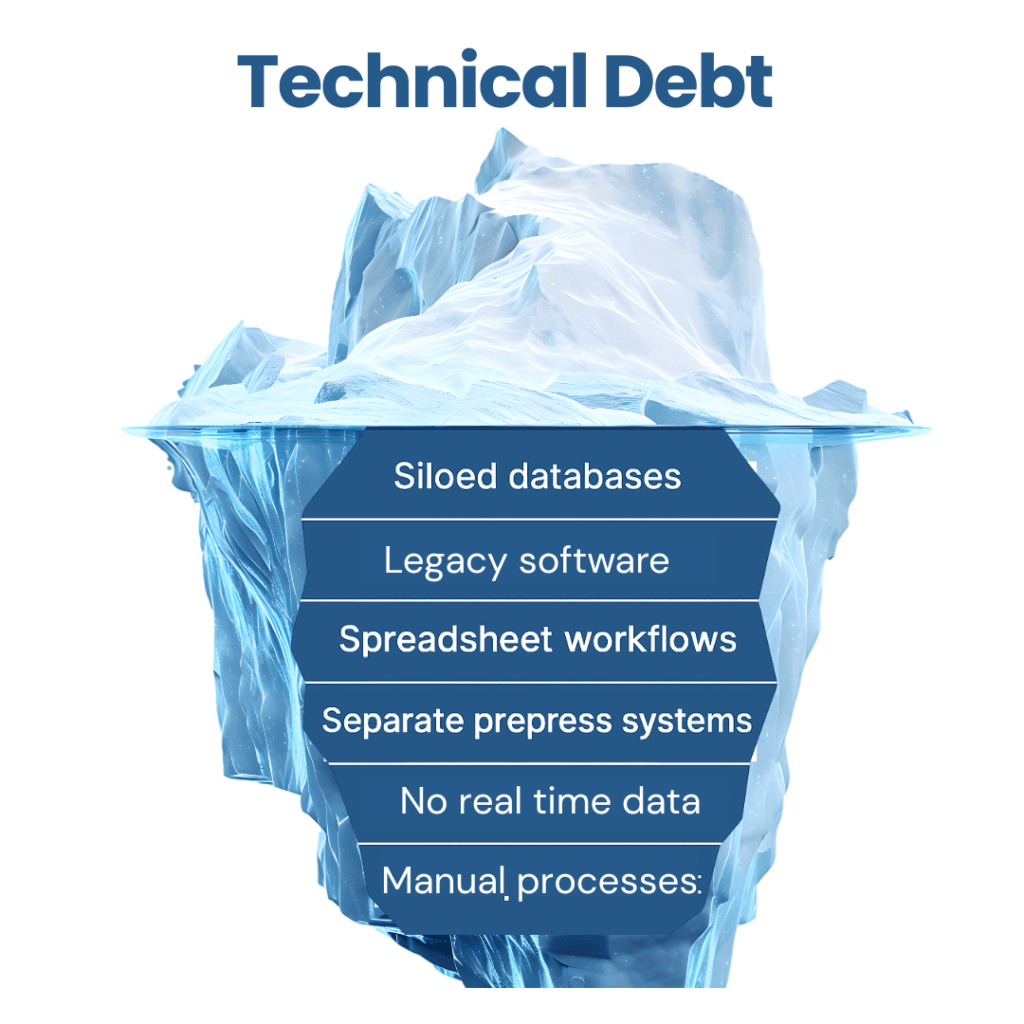

4. Technical Debt: AI Can’t Run on Legacy

Many packaging plants struggle with fragmented systems: siloed databases, partial ERP deployments, unsupported legacy software, spreadsheet workflows, and disconnected prepress/scheduling/procurement systems.

Many packaging plants struggle with fragmented systems: siloed databases, partial ERP deployments, unsupported legacy software, spreadsheet workflows, and disconnected prepress/scheduling/procurement systems.

This “technical debt” actively prevents automation. You can’t deploy AI on systems that can’t share data.

How Modern ERP Systems Help: Unified ERP platforms eliminate technical debt by replacing fragmented systems with a single source of truth. Modern APIs enable seamless integration with specialized tools—prepress workflow systems, MES equipment monitoring, customer portals—while maintaining centralized data management for analytics and reporting for packaging CEOs and leadership. This connected architecture becomes the foundation for AI deployment because it’s all accessible within one system rather than locked in disconnected silos.

5. Short-Runs & the SKU Explosion

Short-run volume increases strain estimating departments, planning and prepress teams, increase waste percentages, and amplify scheduling complexity. SKU proliferation remains one of packaging’s biggest operational disruptors.

Manual systems cannot scale to handle this demand pattern. The only solution: automated workflows with AI-assisted planning that optimizes across thousands of variables simultaneously.

How Modern ERP Systems Help: Sophisticated ERP scheduling engines handle short-run complexity through intelligent algorithms that humans cannot match manually. The system evaluates thousands of sequencing options considering press capabilities and availability, substrate compatibility, die availability, delivery dates, and setup optimization—generating optimal production schedules in minutes rather than hours. It handles SKU proliferation by centralizing product data, automating version control, accelerating estimating, reducing changeovers, and giving packaging CEOs and plant leadership real-time visibility.

6. Traceability: New Requirements in 2026

New North American packaging regulations take effect in 2026—including stricter recyclability-labeling laws like California’s SB 343 and expanding state EPR programs—requiring manufacturers to track & trace.

Brand owners too will demand real-time job status, material and lot traceability, documentation, supplier visibility, and comprehensive reporting. Compliance full lot-level visibility for safety, recalls, and brand protection—make traceability non-negotiable in 2026.

Brand owners too will demand real-time job status, material and lot traceability, documentation, supplier visibility, and comprehensive reporting. Compliance full lot-level visibility for safety, recalls, and brand protection—make traceability non-negotiable in 2026.

Without connected systems from purchase order through logistics to finance, meeting audit demands consumes days of staff time per request.

How Modern ERP Systems Help: End-to-end ERP platforms deliver the full traceability customers expect by linking data across the entire production journey. Each job carries a digital thread—from purchase order to material lots, production timestamps, QC checks, shipping records, and invoicing. Customer portals give real-time access to job status, certificates, and sustainability data, reducing CSR workload. Lot-level tracking enables instant recall response, identifying affected finished goods in seconds.

7. Aging Equipment Forces Choices

With tight margins and volatile demand, packaging CEOs are facing difficult capital expenditure decisions. Presses older than 15 years show rising downtime, generate more waste, and make data collection harder. Skilled operators increasingly prefer modern equipment with better safety features and digital controls.

AI-enabled MES and predictive maintenance become critical for maximizing equipment ROI and making smarter CAPEX decisions.

How Modern ERP Systems Help: Integrated ERP platforms with manufacturing execution system (MES) capabilities track equipment performance in real-time, capturing data that informs both maintenance and investment decisions. Automated job costing by press reveals the true profitability of each machine, accounting for setup time, runtime, downtime, waste rates, and quality issues. Predictive maintenance alerts based on runtime hours, cycle counts, and performance degradation prevent costly unplanned downtime.

8. Sustainability Remains a Major Force in 2026

Sustainable packaging isn’t a “nice to have” anymore—it’s a mandate. Regulations are tightening, and brand owners want CO₂, recyclability, sourcing, and waste data down to the SKU. Packaging plants must now deliver instant material transparency, real-time traceability, verified certifications, and airtight carbon and energy reporting—every job, every run, every time.

How Modern ERP Systems Help: Modern ERPs capture the sustainability data customers and regulators expect by tracking key environmental metrics across production. They record material sourcing, recycled content, and supplier certifications, while production data calculates energy use, waste, and carbon footprint per job. Automated reporting generates sustainability scorecards and certificates—no manual compilation. Brands can request carbon data, turning sustainability from a compliance task into a competitive advantage.

9. The AI Tipping Point Has Arrived

AI isn’t optional in 2026—it’s the new competitive baseline. According to McKinsey’s State of AI 2025 , 88% of companies are now using AI in at least one business function, and firms embedding AI in operations report the highest ROI. Meanwhile, NAPCO Alliance Insights study finds 85% of packaging and print companies view AI as essential to competitiveness.

AI isn’t optional in 2026—it’s the new competitive baseline. According to McKinsey’s State of AI 2025 , 88% of companies are now using AI in at least one business function, and firms embedding AI in operations report the highest ROI. Meanwhile, NAPCO Alliance Insights study finds 85% of packaging and print companies view AI as essential to competitiveness.

And the financial statistic is undeniable: KPMG’s Intelligent Manufacturing Report 2025 finds 96% of manufacturers gain efficiency and 45% see real financial returns in year one.

The fastest wins for packaging CEOs? Estimating, Procurement, Logistics, and Accounts Payable—where AI slashes time, cost, and manual work instantly.

Bottom Line: Insights for 2026

Every major research organization—Deloitte, McKinsey, PMMI, NAPCO—delivers the same message:

AI-driven workflow automation is now the core operational requirement for packaging success in 2026.

Facing a defining moment in 2026? See how an AI-powered ERP turns 2026’s challenges into advantages.

Additional articles you might find valuable

Bridging the Gap: Leveraging an ERP/MIS to Mitigate Skilled Labor Shortages

SUMMARY The skilled labor shortage has become a significant challenge across various industries, with sectors like manufacturing, logistics, and packaging feeling the impact most acutely. As the demand for skilled labor continues to outpace supply, organizations are...

Shop Floor Scheduling: Are You Getting the Most out of Your Plant’s Production Capacity?

SUMMARY Summary: SEMrush data from 2024 shows that companies integrating advanced scheduling technologies experience a 25% increase in production efficiency. Getting the most out of your plant’s capacity means implementing a robust ERP that helps plan, execute, and...

Seeing is Believing: Exploring HiFlow’s Highly Visual Workflow

SUMMARY Sometimes it can be difficult to quickly get to a full 360-degree view of the converter’s operation, including both production and business elements. That’s why HiFlow developers have placed a strong focus on developing a highly visual representation of a...