SUMMARY

The packaging industry stands at the brink of a transformative era. As we step into 2025, advancements in technology promise to redefine the way businesses operate, compete, and deliver value. CEOs, CFOs, and CTOs in the packaging sector are increasingly attuned to these changes, as they represent not just opportunities but imperatives for survival.

A Day in the Life of a Packaging Manufacturer 2025: AI Enhanced

It’s 7:30 a.m. on a crisp Monday morning in 2025. Sarah, the plant manager at a cutting-edge packaging manufacturing facility, walks onto the production floor. Her tablet buzzes with an AI-generated alert—analyzing real-time order data, the system has identified a potential bottleneck in today’s production schedule. Without missing a beat, Sarah opens the AI scheduling tool, which has already recalibrated the ideal workflow, optimizing machine assignments and labor allocation to ensure on-time delivery.

Meanwhile, across the floor, Tim, a skilled estimator, reviews the morning’s tasks. Instead of spending hours manually inputting job costs and estimating materials, Tim relies on the AI-powered job costing and estimating tool. In seconds, it quickly evaluates historical data, material prices, and machine capabilities to deliver precise estimates, then creates the optimum layout. Tim is now freed to focus on getting the next quote out to the busy sales team.

Later in the day, Sarah’s AI purchase order processing system flags a sudden spike in purchase order emails. With a few taps, the AI suggests responses with detailed information, accelerating order processing and ensuring data consistency. AI then creates and fulfills individual PO positions, allocating and tracking resources with accuracy. Once the PO is generated, the AI attaches a PDF version and an acknowledgment email goes out. Seconds are all it takes.

At the same time, AI analytics delivers a comprehensive dashboard highlighting key performance metrics, enabling Sarah to identify trends, resolve inefficiencies, and make strategic decisions with confidence.

This isn’t science fiction—it’s the power of AI in ERP systems, revolutionizing how packaging manufacturers operate. By automating routine tasks, enhancing accuracy, and empowering skilled professionals, AI is not just transforming the industry but creating a future of efficiency, innovation, and profitability.

The packaging industry stands at the brink of a transformative era. As we step into 2025, advancements in technology promise to redefine the way businesses operate, compete, and deliver value. CEOs, CFOs, and CTOs in the packaging sector are increasingly attuned to these changes, as they represent not just opportunities but imperatives for survival.

Additionally, small and medium-sized businesses (SMBs) in the packaging sector are likely to bear the brunt of these changes. As Sylvia Ng, CEO of ReturnBear, explains, “SMBs don’t have the bandwidth or the extra resourcing to handle all this change.” Increased tariffs will necessitate a reassessment of supply chains—a costly and time-consuming endeavor. Source: FreightWaves.

AI in ERP: The 2025 Version

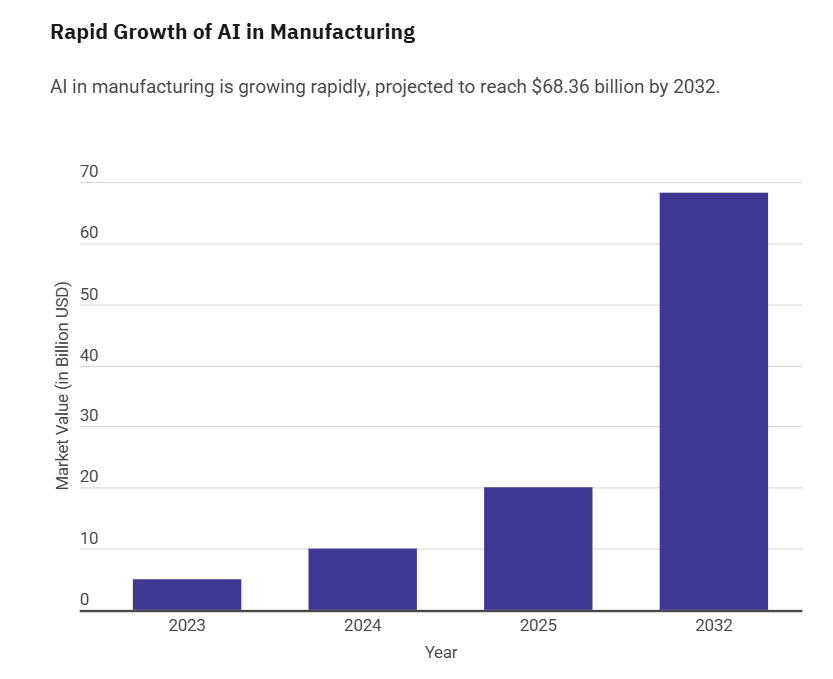

According to Packaging Impressions and other leading packaging media sources, artificial intelligence (AI) is rapidly becoming a cornerstone of next-generation ERP (Enterprise Resource Planning) systems. By 2025, these AI-powered solutions will enable packaging manufacturers to tap into new levels of decision intelligence, particularly in the areas of predictive maintenance, real-time production optimization, and accurate demand forecasting. For executives, this means greater agility in responding to changing market demands and uncovering hidden inefficiencies.

Packaging Impressions highlights how AI algorithms can continuously monitor machine performance and diagnose potential issues before they disrupt production, thereby reducing downtime and preventing costly interruptions. The same technology also analyzes live data from sensors, production lines, and external market factors, allowing businesses to optimize scheduling, minimize material waste, and maintain consistent quality. By improving forecasting capabilities, AI helps prevent both stockouts and overstocking, ultimately enhancing cash flow and operational flexibility.

Many media outlets refer to AI-driven ERP systems as “efficiency engines,” emphasizing their ability to automate procurement, adjust schedules on the fly, and anticipate equipment maintenance needs. In an era when order volumes shift rapidly and product lifecycles continue to shorten, these features are critical for maintaining competitiveness. AI can optimize the purchase of materials by using real-time consumption data, helping avoid unnecessary expenses and logistical complications. Similarly, AI-powered scheduling tools balance workloads, machine availability, and operator skill sets, thereby reducing production bottlenecks and ensuring an efficient workflow.

When integrated with ERP solutions, AI bolsters end-to-end operational visibility and automation across the packaging manufacturing process. Combining IoT sensors on machines with AI-driven ERP systems ensures real-time tracking of inventory, improving accuracy and reducing waste. Instead of relying on traditional, time-based maintenance schedules, predictive maintenance powered by AI flags parts or machinery that need servicing, often before issues escalate. This approach minimizes unforeseen breakdowns and helps maintain tighter production schedules. The result is an advanced level of efficiency and responsiveness that keeps manufacturers competitive in a world where consumers demand rapid turnaround times and strict compliance with quality standards.

Data and Analytics in 2025

Data and analytics are the holy grail of packaging advancements, enabling smarter decisions and long-term sustainability improvements.

1. Driving Sustainability: Data provides the foundation for sustainability initiatives. With access to real-time analytics, companies can make informed choices before production begins. Comparative assessments empower businesses to select materials and processes that align with sustainability goals, reducing environmental impact.

2. Tracking Progress Over Time: Historical data creates a comprehensive record of a company’s carbon footprint improvements. This aggregated insight offers leaders the ability to measure the effectiveness of their sustainability strategies. As Susie Stitzel, Director of Product Management at Esko, aptly notes, “Companies are increasingly seeking data for a holistic view of their sustainability progress. They need aggregated insights across projects to understand their environmental impact in real-time.”

3. Advanced data collection and visualization tools integrated with AI-powered ERP systems provide unparalleled insights into production costs, customer preferences, and market trends. These tools allow manufacturers to make informed decisions faster, optimizing inventory and maximizing profitability. For packaging professionals, leveraging data isn’t just about compliance; it’s about driving innovation and gaining a competitive edge.

Source: AllAboutAI

Automation: The Productivity Catalyst

In 2024, automation was cited as one of the top three contributors to business success by industry leaders, alongside quality and standardization. This momentum will only grow in 2025.

Streamlining Operations: Automation in prepress processes, production workflows, and team handovers minimizes human error, boosts precision, and accelerates time-to-market. Jan De Roeck from Esko highlights automation’s flexibility, stating, “It allows brands to adapt quickly to changing market demands while keeping packaging inventory (and the capital locked into that inventory) as low as possible.”

Standardizing Post-M&A Workflows: With mergers and acquisitions continuing into 2025, increasing, automating and standardizing workflows across facilities has become essential. Unified systems ensure resource optimization and seamless job balancing.

Source: Deloitte

Automation: Productivity at Scale

Automation technologies, such as robotic arms and smart printing presses, enable manufacturers to meet rising demand with speed and precision. For example, the flexible plastic packaging market is projected to surpass $250 billion by 2032, indicating significant growth and the need for efficient production capabilities.

Survey data from Esko’s 2025 reveals that 42% of respondents believe automation will have the most significant impact on the packaging industry in 2025—a testament to its transformative potential.

Disruptive Trends Shaping Packaging Technology in 2025

The packaging industry is on the cusp of significant transformation. As we navigate through 2025, several disruptive trends are poised to redefine how businesses operate, compete, and deliver value. For CEOs, CFOs, and CTOs in the packaging sector, understanding these developments is crucial to staying ahead. Let’s delve into the key trends shaping the future of packaging technology.

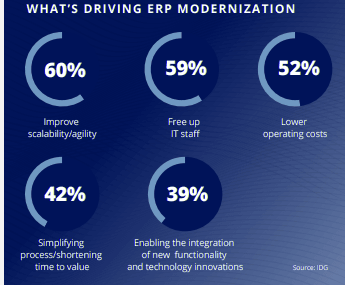

Enterprise Resource Planning (ERP) systems are evolving to meet the unique demands of packaging manufacturers, driven by advancements in technology and a focus on sustainability.

1. AI-Driven Decision Intelligence: AI-powered ERP systems offer predictive analytics for maintenance and real-time optimization of production schedules, enabling executives to make data-backed decisions swiftly.

2. Hyper-Automation: Integrating technologies like Robotic Process Automation (RPA) and IoT sensors into ERP systems automates repetitive tasks, allowing organizations to scale operations without increasing labor costs.

3. Unified Ecosystems: Modern ERP solutions connect all aspects of the business—production, sales, supply chain, and customer service—providing a 360-degree view of operations and eliminating silos.

4. AI-Augmented Costing and Estimating: Advanced algorithms analyze historical data to deliver precise quotes and job costs, reducing pricing errors and enhancing customer satisfaction.

A Tech Look Ahead: Trends Shaping the Industry in 2025

The Rise of Packaging-Specific ERP Systems

Generic ERP systems are becoming obsolete. The rise of industry-specific ERPs in 2025 reflects a growing demand for tailored solutions that address the unique challenges and nuances of specific sectors, such as packaging, flexible packaging, and label manufacturing. Unlike traditional, one-size-fits-all ERP platforms, these specialized systems come pre-configured with features, workflows, and tools designed to align with the industry’s processes, regulatory requirements, and operational goals.

Sustainability Goals Assisted by ERP

Consumer demand for eco-friendly solutions is reshaping the packaging industry. 80% of those who responded to the Esko Packaging Trends 2025 Survey indicated environmental sustainability will be important to their company for packaging in 2025. ERP systems help packaging manufacturers meet sustainability demands by optimizing resource usage, reducing waste, and improving energy efficiency. It ensures compliance with environmental regulations like EPR and recycled content mandates while offering tools for supplier evaluation, carbon footprint tracking, and sustainable product design. ERPs generate compliance reports for

Extended Producer Responsibility (EPR) Regulations in 2025

In 2025, the regulatory landscape for packaging, flexible packaging, corrugated, and label converters is characterized by heightened environmental standards and extended producer responsibilities. Several U.S. states have enacted EPR laws, mandating producers to manage the lifecycle of their packaging materials. Oregon is set to implement its EPR program in July 2025, requiring producers to submit initial supply reports by March 31, 2025.

A Day in the Life of a Packaging Manufacturer 2025: Leadership Transformed by AI-Driven ERP

It’s a pivotal morning in 2025, and the executive team at a leading packaging manufacturing company gathers in their state-of-the-art boardroom. The CEO, Thomas, reviews a strategic growth opportunity with the team. The AI-powered ERP system has analyzed market trends, customer data, and competitor activity, identifying untapped regions for expansion and a niche product line with rising demand. Armed with this data-driven insight, Thomas outlines a bold vision for growth, confident in the system’s ability to minimize guesswork and maximize results.

Next, the CFO, Liam, dives into the financial metrics displayed on the AI-driven analytics dashboard. Real-time cost analysis has uncovered inefficiencies in raw material sourcing, along with opportunities for supplier negotiations. The system has also flagged potential risks in currency fluctuations for overseas suppliers, recommending strategies to hedge against these risks. For Liam, AI is no longer just a tool—it’s an essential ally for improving cost management and safeguarding the company’s bottom line.

Meanwhile, the CTO, Vanessa, discusses how these innovations align with the company’s broader technology roadmap. Partnering with an ERP provider at the forefront of AI-ERP integration has allowed the company to stay competitive, adapt to emerging challenges, and remain agile. Vanessa emphasizes the importance of maintaining this partnership to future-proof operations and support the company’s growth ambitions.

Together, the executive team sees the impact of AI not only on operational efficiency but also on strategic decision-making. For CEOs, it offers pathways to differentiate and lead in a crowded market. For CFOs, it delivers better financial control and risk mitigation. For CTOs, it underscores the value of investing in cutting-edge technology to secure long-term success.

This is the future of leadership in packaging manufacturing—where AI in ERP systems transforms every level of the business, driving growth, innovation, and resilience.

‘Shaped by new technology, shifting consumer preferences, and a growing focus on sustainability, the packaging industry is always changing. It is incumbent on packaging professionals to seize all opportunities to boost sustainability, to leverage the latest technological advancements, to refine supply chain processes and ultimately to improve their operational efficiency,” said Matthew Haws, chief marketing officer at Esko in Esko’s 2025 Packaging Trends.

In conclusion, the packaging industry’s shift toward a more technology-driven, sustainable, and competitive landscape underscores the critical role of ERP systems. Modern ERP solutions are evolving to address the sector’s most pressing demands—AI integration, sustainability, regulatory compliance, and supply chain agility. From optimizing resource management to enabling data-driven decisions, these systems are no longer optional but essential for businesses striving to stay ahead. CEOs, CFOs, and CTOs must embrace these trends, leveraging ERP capabilities to navigate challenges and seize opportunities in this transformative era, ensuring resilience and relevance in the years to come.

The future of packaging is being reimagined. Are you ready to lead the transformation?

+ Connect with us and feel free to leave a comment on one of our channels.

Additional articles you might find valuable

Bridging the Gap: Leveraging an ERP/MIS to Mitigate Skilled Labor Shortages

SUMMARY The skilled labor shortage has become a significant challenge across various industries, with sectors like manufacturing, logistics, and packaging feeling the impact most acutely. As the demand for skilled labor continues to outpace supply, organizations are...

Shop Floor Scheduling: Are You Getting the Most out of Your Plant’s Production Capacity?

SUMMARY Summary: SEMrush data from 2024 shows that companies integrating advanced scheduling technologies experience a 25% increase in production efficiency. Getting the most out of your plant’s capacity means implementing a robust ERP that helps plan, execute, and...

Seeing is Believing: Exploring HiFlow’s Highly Visual Workflow

SUMMARY Sometimes it can be difficult to quickly get to a full 360-degree view of the converter’s operation, including both production and business elements. That’s why HiFlow developers have placed a strong focus on developing a highly visual representation of a...