Shop Floor

Data Collection

Introduce Industry

4.0 to your plant

Collect, measure and report critical information in real time

MIS and Shop Floor Data Collection.

A powerful duo.

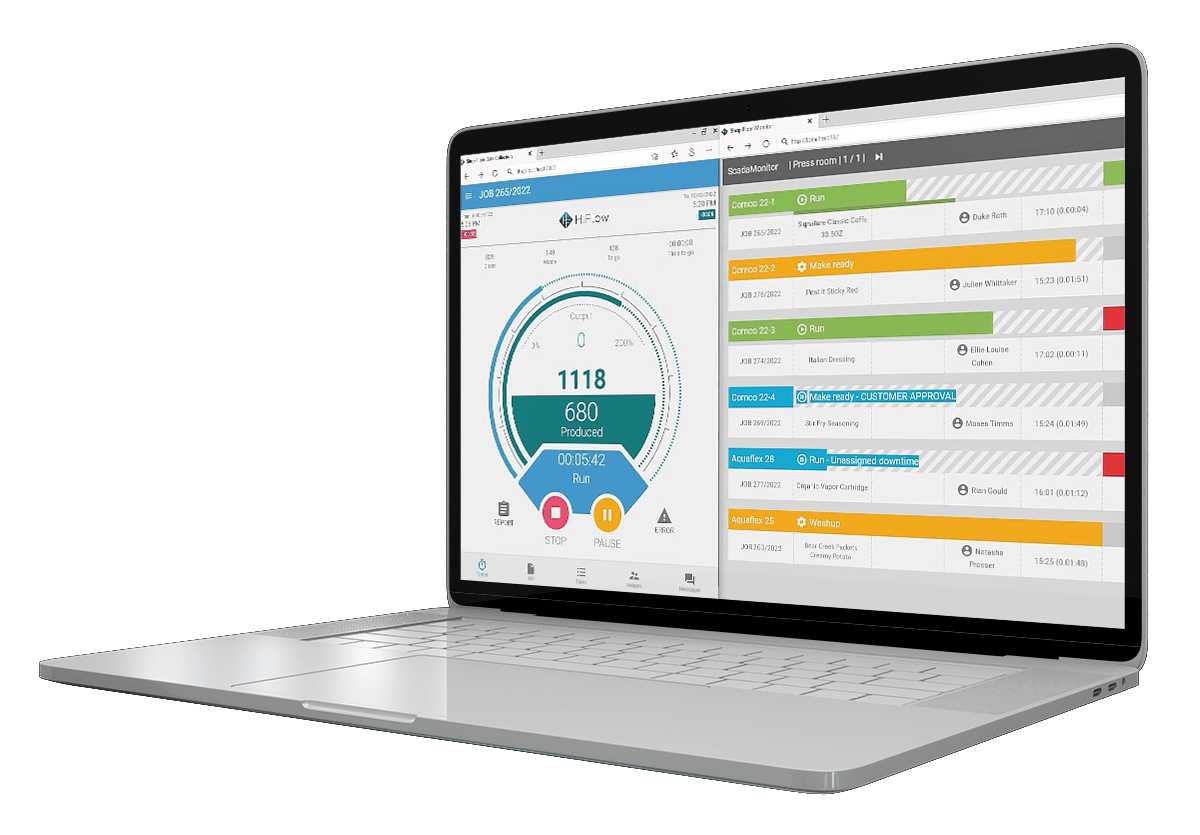

A shop floor data collection module (also referred to as MES) is a valuable addition to an MIS, providing powerful capabilities. Give your team the data they need to be productive and proactive.

Shop Floor Operators

Data collected on the shop floor about machine statuses ensures they’re meeting production goals.

Plant Managers

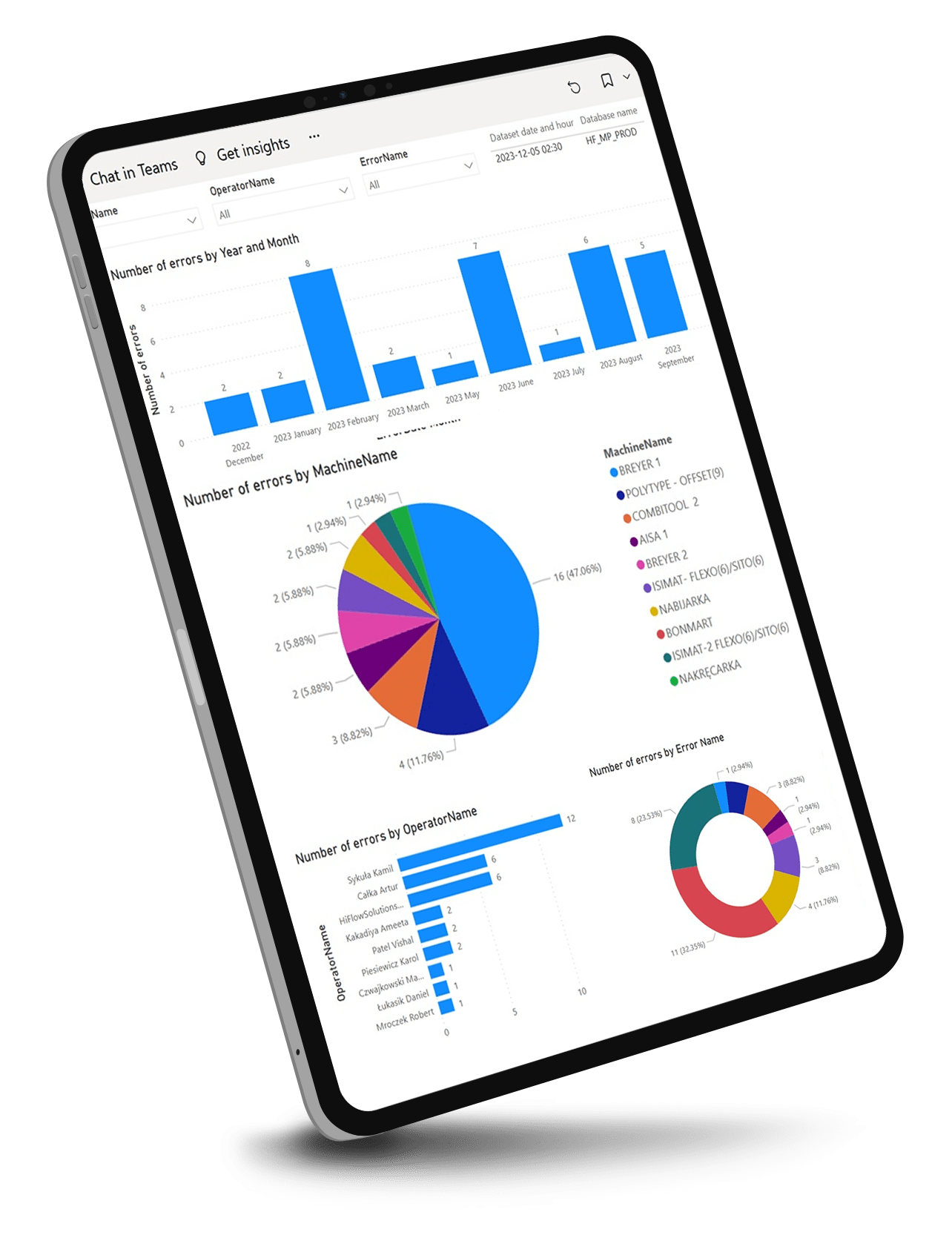

HiFlow’s Dashboards display operator performance, inventory and production conditions – minimizing bottlenecks and downtime.

COOs

COOs get insights into day to day operations — data on plant, department, machine, operator, warehouse, jobs.

Inventory Management

When shop floor data collection is well-integrated with an MIS, managing inventory becomes easier. By establishing min/max inventory levels for both raw materials and finished goods (e.g., for kitting and fulfillment), inventory levels can be restocked automatically, ensuring adequate inventory levels at all times. Plus, shop floor data collection systems make job costing and estimate-to-actual comparisons extremely accurae. LEARN MORE

What is Shop Floor Data Collection?

The Shop Floor Data Collection module, also referred to as MES, is a Smart Factory in action. With the real-time collection of manufacturing data your plant already produces, gain increased visibility into the entire production process from end to end.

A shop floor data collection module connects the dots among machines, processes and people by collecting data points at all levels of your packaging business.

Your plant generates hundreds of data points every millisecond – what happened in the past, what’s happening now, and what will happen next.

It feeds this data to your MIS in real time so you can quickly measure, understand, and optimize systems across your business ecosystem.

Shop Floor Data Collection (MES) is the heart of Industry 4.0 and the Smart Factory.

Shop Floor Data Collection

The Shop Floor Data Collection module is Smart Factory in action. With the real-time collection of manufacturing data your plant already produces, gain increased visibility into the entire production process from end to end.

Shop Floor Data Collection enhances inventory systems

Connect data points from your warehouse to HiFlow’s Dashboards.

Taking data from each scheduled job, the shop floor data collection (MES) module supplies a ‘shopping list’ of what needs to move to the floor on a just-in-time basis. Along with HiFlow’s WMS and Production modules, WIP inventory space is reduced, reducing overall costs.

Control visibility and traceability and track the entire inventory, including semi-finished and finished products with HiFlow’s Shop Floor Data Collection (MES) modules.

Optimized production monitoring

PRODUCTION SCHEDULING ANALYTICS

Shop floor data collection connections produce real-time data on all your jobs in production with smart scheduling. Optimize performance by scheduling, timing, and sequencing activities based on priorities and resource capacity.

TOOLS TRACKING

Get tools availability at the right time and alerts for potential tool-related bottlenecks. The shop floor data collection module automatically collects data on tool usage, production run and repair.

It also collects machine data such as planned versus actual production, unplanned downtime, real-time production quality, and Overall Equipment Efficiency (OEE).

Control costs and keep inventories lean

Get a clear picture of actual materials used in production and real time updates of inventory. Facilitate dynamic resource allocation by using real-time data collected on machine availability, production schedules, and material requirements.

Stay on top of your jobs from raw material through the various production stages, including semi-finished products and finished goods in the warehouse. The shop floor data collection module generates production data that can be analyzed for insights into production efficiency, cycle times, and other KPIs.

Automatic Material Issuing

Uses automation to issue materials from inventory to the job, and after the job is finished, saving time needed to track and issue materials.

Production Tracking

Production Tracking allows manufacturers to track the usage of raw materials and packaging components for each production run.

Improved quality control

A shop floor data collection module (or MES) tracks the entire production cycle from beginning to end — improving product tracking and genealogy, which is essential for manufacturers who must meet regulatory compliance and transparency requirements.

HiFlow meets FDA guidelines 21 CFR Part 11 and 21 CFR Part 210/211, as well as EU GMP guidelines including the GMP Annex 11 for Computerized Systems Guidelines.

QUALITY CONTROL

Create detailed quality processes, quality control plans, and define Key Performance Indicators (KPIs) to be achieved as part of a specific control procedure.

Connect all your departments.

Connect all your plants.

Manufacturing Execution Systems enable the flow of information from shop floor level to business level.

Shop floor data collection connects multiple plants, sites and vendors’ live production information. It integrates with all your machines, equipment, controllers and enterprise business applications.

The result? Complete visibility, control and optimization of production and processes across your entire business ecosystem.

Just the TECH please…

HiFlow’s Shop data collection module (MES) connects to smart sensors on machines, peripherals, PLCs and SCADA as well as operator inputs.

Acquire historical data to evaluate production processes, identify areas of inefficiency and lost production through SCADA networks.

Rules-based workflows for any shop floor data item, machine conditions, alarms, performance metrics, KPIs.

Access to live SPC charts and alarms.

SMART FACTORY, INDUSTRY 4.0 & Internet of Things (IOT)

HIFLOW DRIVES BUSINESS TRANSFORMATION

THROUGH DATA COLLECTION

Shop Floor Data Collection. Find out more

Want to learn more about shop floor data collection, Machine Execution Systems, and the differences between MIS and ERP?

Schedule a walkthrough of our software with our technical staff, customized to address the unique needs of YOUR company and answer all of your questions fully and transparently.

Follow us on LinkedIn to stay current on the latest industry trends and new developments at HiFlow.